Buy VERO Machining Strategist Software

October 2025 Sale!

Limited time: 5% discount on all products! Ends November 1.

Vero Machining Strategist

| Version | Price & Buy |

|---|---|

| 2020 R1 x64 (Hexagon) | |

| 2018 R2 x64 | |

| 2017 R2 x64 |

What Is Machining Strategist Software and How Does It Work?

Core Functionality for CNC Machining

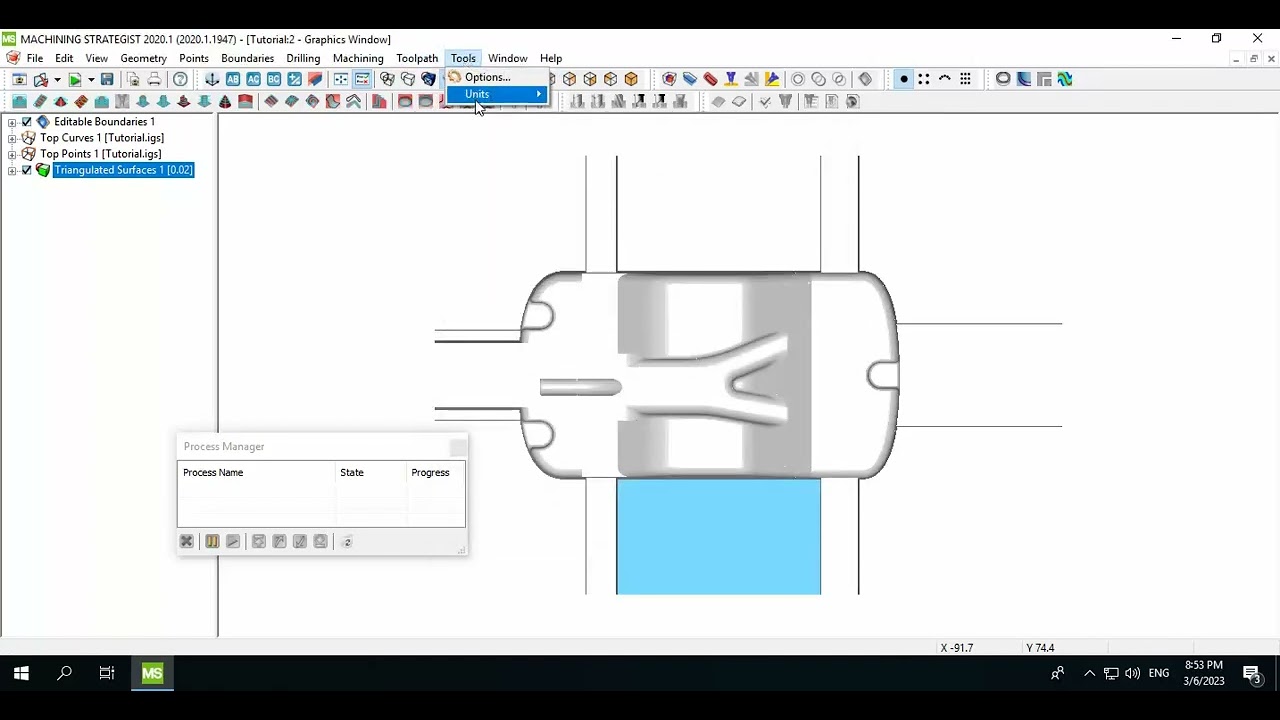

This software excels at generating optimized toolpaths for complex 3D surfaces found in mold cavities, aerospace components, and precision parts. The multi-threaded architecture processes toolpath calculations in the background while you continue working on the same model, eliminating the downtime that plagues other CAM systems. You can view, rotate, and even edit your part geometry while toolpaths calculate, maintaining productivity throughout your programming session.

The waveform roughing technology stands out by maintaining constant tool engagement with the material, which prevents the tool overload that occurs when cutting into corners with traditional offset patterns. This constant engagement approach allows feed rates to remain at optimal values throughout the entire cycle without manual intervention. The result is predictable machining behavior that extends tool life while accelerating material removal.

CAD File Import and Processing Capabilities

Machining Strategist works directly with 3D geometry from virtually any source without requiring the original CAD software to be installed. It imports standard file formats including IGES, STL, VDA-FS, and native files from SolidWorks, CATIA, and other major modeling systems. This CAD-independent approach means your shop can accept jobs from any customer regardless of what software they use for design work.

The geometry processing engine handles large, complex models efficiently, calculating toolpaths in minutes rather than hours. Batch processing capability allows multiple toolpath operations to run simultaneously, which is particularly valuable when programming families of similar parts or generating multiple finishing strategies for comparison.

What Are the Key Benefits of Using Machining Strategist?

Speed and Efficiency Advantages

Programming time drops dramatically compared to traditional CAM approaches. Jobs that previously required several hours of programming work now complete in under an hour. One aerospace machining shop reported creating accurate quotes within 60 minutes of receiving customer 3D models, a timeline that would be impossible with conventional CAM systems.

The software's calculation speed allows real-time experimentation with different strategies. You can test multiple finishing approaches, compare cycle times, and select the optimal path before committing to production. This rapid iteration capability proves invaluable when dealing with tight deadlines or complex geometry that requires strategic planning.

- Generate complete 3-axis toolpaths in minutes instead of hours

- Continue working on models while toolpath calculations run in background

- Process multiple operations simultaneously through batch calculation

- Create accurate job quotes within one hour of receiving customer files

Superior Surface Finish Quality

High-speed machining strategies produce polished surfaces straight from the CNC machine, significantly reducing or eliminating manual finishing work. The optimized toolpaths minimize tool marks and maintain consistent surface texture across complex contoured areas. Shops working on mold cavities report substantial reductions in polishing labor after implementing these advanced toolpath techniques.

The software calculates optimal cutting parameters automatically based on geometry complexity and tool engagement. Feed rates adjust dynamically to maintain surface quality even when transitioning between flat areas and complex curves. This intelligent adaptation prevents the surface irregularities that occur when using fixed parameters across varying geometry.

Tool Life Extension and Cost Reduction

| Benefit Area | Traditional Toolpaths | Machining Strategist |

|---|---|---|

| Tool Engagement | Variable (overload in corners) | Constant throughout cycle |

| Cutting Force | Peaks and valleys | Steady and predictable |

| Heat Generation | Concentrated at tool tip | Distributed along flute length |

| Tool Wear Pattern | Concentrated wear zones | Even wear distribution |

The constant engagement approach distributes cutting forces evenly, preventing the shock loads that cause premature tool failure. Cutting occurs along the full flute length rather than concentrating wear at the tool tip, which effectively extends usable tool life. Heat dissipates through the chip rather than accumulating in the tool, further reducing thermal wear that degrades cutting edges.

Toolholder collision detection prevents costly crashes that damage tools, fixtures, and machine spindles. The software automatically checks clearances and alerts you to potential gouge conditions before code reaches the shop floor. This proactive protection eliminates the expensive mistakes that occur when relying solely on visual verification or trial cuts.

Which Industries and Applications Benefit Most from Machining Strategist?

Mold and Die Manufacturing

Complex cavity work with multiple detailed surfaces represents the ideal application for this technology. The software handles intricate core and cavity geometry efficiently, generating smooth toolpaths that follow compound curves without hesitation. Steep walls, tight radii, and deep pockets all process cleanly with appropriate toolpath strategies applied automatically.

Rest machining intelligence identifies leftover material from previous operations, focusing subsequent passes only where needed. This targeted approach eliminates air cutting and reduces cycle times on parts with varying depth features. The software calculates exactly where material remains rather than requiring manual stock definition or conservative assumptions.

Aerospace Component Production

High-precision contoured surfaces with demanding tolerance requirements benefit from the optimized toolpath quality. The software maintains consistent surface finish across large workpieces, critical when machining aluminum structural components or titanium engine parts. Dimensional accuracy remains stable even on lengthy machining cycles because cutting forces stay predictable throughout the operation.

Hard material machining becomes more practical with the constant engagement approach that prevents tool breakage. Aerospace shops working with Inconel, titanium alloys, or hardened steel report improved success rates when using waveform roughing versus traditional strategies. The software's ability to maintain high feed rates in difficult materials directly translates to faster project completion.

High-Volume Production Environments

| Production Scenario | Key Advantage | Business Impact |

|---|---|---|

| Repeat Parts | Batch processing automation | Unattended toolpath generation |

| Similar Components | Template-based programming | Consistent quality across part families |

| Rush Orders | Rapid quote generation | Faster response to customer inquiries |

| Capacity Planning | Accurate cycle time prediction | Reliable delivery commitments |

The fast programming cycle allows shops to accept more jobs without increasing engineering staff. Quick turnaround on quotes improves win rates for new business opportunities. Accurate cycle time estimates enable realistic scheduling and on-time delivery performance.

How Does Machining Strategist Integrate with Your Existing Workflow?

CAD System Compatibility

The software sits downstream from your design environment, accepting geometry from any major CAD platform. Design changes flow smoothly because you simply reimport the updated model and regenerate affected toolpaths. This flexibility proves essential when working with customers who use different CAD standards or when design iterations occur during the manufacturing phase.

File translation happens automatically without manual intervention or intermediate conversion steps. Surface quality from the original CAD model transfers intact, ensuring toolpath accuracy matches design intent. The software reads tessellated data (STL files) equally well as precise mathematical surfaces, giving you options when working with different file sources.

Shop Floor and Office Deployment Options

Installation works equally well in the programming office or directly on the shop floor near CNC equipment. The straightforward interface allows competent machinists to generate toolpaths without extensive CAM background. This accessibility means you can distribute programming tasks rather than bottlenecking all CAM work through a single specialist.

- Deploy on engineering workstations for centralized programming

- Install at machine locations for immediate program adjustments

- Run on standard Windows hardware without specialized requirements

- Share CAM data across network for collaborative programming

Post-processor support covers major CNC controller families, ensuring compatibility with your existing machine tools. Custom post-processors can be created for proprietary or modified controllers. The output code format matches what your operators expect, minimizing confusion and reducing setup errors.

How Easy Is It to Start Using Machining Strategist?

User Interface and Operational Simplicity

The interface focuses on getting results rather than requiring deep technical knowledge of CAM theory. Competent machinists become productive within days because the software automates complex decisions that other systems force users to make manually. You select basic parameters like tool diameter and desired finish quality, then the software calculates appropriate strategies automatically.

Visual feedback shows exactly what the tool will cut before generating final code. Toolpath preview displays in the same window as your 3D model, making verification intuitive and quick. Color-coded displays indicate cutting direction, feed rates, and potential issues that require attention.

Multi-Tasking and Productivity Features

The background calculation architecture represents a significant workflow advantage over conventional CAM systems. When toolpath generation starts, you immediately return to working on other aspects of the job. You can set up subsequent operations, review previous toolpaths, or even begin programming a different part entirely.

Progress indicators show calculation status without interrupting your work. If you notice an error in your setup, you can cancel the current calculation and restart with corrected parameters in seconds. This responsive behavior eliminates the frustration of waiting for lengthy calculations only to discover a setup mistake.

Batch processing takes this concept further by queuing multiple operations. You define all required toolpaths, then let the software calculate everything while you focus on other tasks. The system works through the queue automatically, completing a full job setup without constant supervision.

Frequently Asked Questions About Machining Strategist

Simple 3-axis toolpaths calculate in minutes, while complex multi-operation sequences complete in under an hour. The exact time depends on part complexity and computer performance, but the multi-threaded architecture ensures calculations proceed as fast as your hardware allows. Background processing means you continue working regardless of calculation time.

The software specifically targets high-speed machining applications with spindle speeds up to 24,000 RPM. Toolpath strategies optimize for rapid traverse rates and high feed velocities common in modern CNC equipment. The waveform roughing approach maintains constant velocity through curves, which allows high-speed machines to perform at their full capability.

Shops report substantial reductions in hand-finishing labor after implementing optimized finishing strategies. The improved surface quality comes directly from the CNC machine, often eliminating the need for abrasive polishing on visible surfaces. Parts with critical aesthetic requirements may still need some hand work, but the starting surface quality is significantly better than conventional toolpath approaches produce.

The software generates realistic cycle time estimates that account for actual cutting conditions, not just theoretical calculations. One aerospace shop creates complete quotes within one hour of receiving customer 3D models, including accurate machining time predictions. This speed and accuracy improves bid competitiveness while reducing the risk of underestimating job complexity.

The software imports IGES, STL, VDA-FS, and native formats from major CAD systems including SolidWorks and CATIA. This broad compatibility means you can accept work from any customer regardless of their design software preferences. File translation occurs automatically without intermediate conversion steps or quality loss.

Built-in toolholder collision detection automatically checks clearances and alerts you to potential gouge conditions before code reaches the shop floor. This proactive protection prevents costly crashes that damage tools, fixtures, and machine spindles. The software validates toolpaths against holder geometry, not just cutting tool dimensions.

The software provides comprehensive strategies for both material removal and surface finishing. Waveform roughing maintains constant engagement for efficient stock removal, while dedicated finishing algorithms produce polished surfaces with minimal tool marks. You can program complete manufacturing sequences from raw stock to finished part within a single environment.