Buy Mastercam Software

October 2025 Sale!

Limited time: 5% discount on all products! Ends November 1.

Mastercam

| Version | Price & Buy |

|---|---|

| 2026 | |

| 2025 with Update 7 | |

| 2024 with Update 6 | |

| 2023 with Update 4 x64 | |

| 2022 with Update 3 x64 | |

| 2021 with Update 1 x64 | |

| 2020 x64 | |

| 2019 x64 | |

| 2018 x64 | |

| 2017 x64 | |

| X9 x64 | |

| X8 x64 | |

| X7 |

What Is Mastercam Software?

Mastercam provides manufacturers with an integrated environment for designing parts and generating CNC toolpaths. The software works with virtually any machine type and accepts CAD files from all major design platforms, which means it fits into existing workflows without forcing system changes.

The platform has become standard across manufacturing because it addresses the complete programming cycle. You can import designs, create toolpaths, verify programs through simulation, and generate machine-ready G-code—all within one interface.

Complete CAD/CAM Integration

Import geometry from SolidWorks, Inventor, CATIA, or any other CAD system and start programming immediately. Mastercam's universal file compatibility eliminates translation errors and keeps your design intent intact throughout the manufacturing process.

The software includes native CAD tools for modifying imported geometry or creating fixtures and tooling. This dual capability means programmers can make necessary adjustments without bouncing between applications.

Industry-Leading Adoption

Shops worldwide use Mastercam because it delivers consistent results across diverse operations. When you hire someone with Mastercam experience, they can contribute immediately—the software's widespread adoption means trained programmers are available.

Why Manufacturers Choose Mastercam

- Intelligent toolpaths prevent tool overload and extend cutting tool life by maintaining optimal engagement throughout the cut

- Built-in simulation catches collisions and programming errors before they cause machine damage or scrapped parts

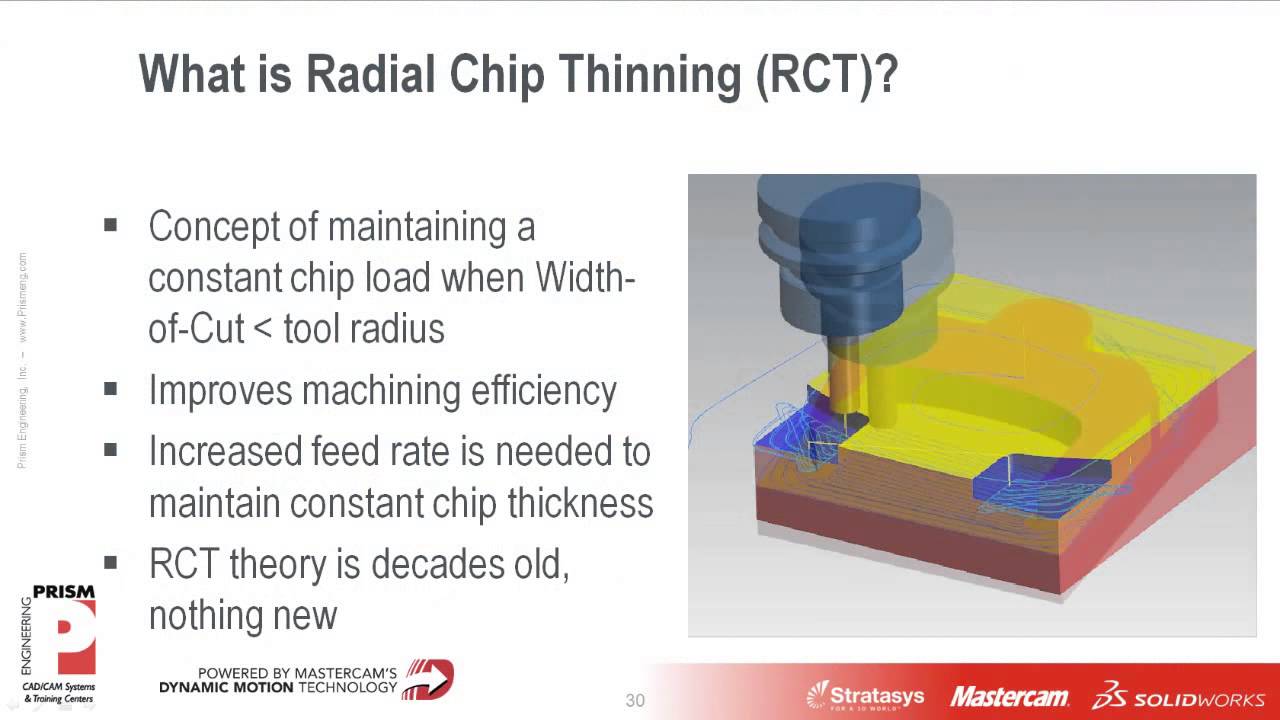

- Dynamic Motion technology reduces cycle times while producing superior surface finishes compared to conventional toolpaths

- Universal machine support works with mills, lathes, routers, and mill-turn centers from any manufacturer

Error Prevention Through Simulation

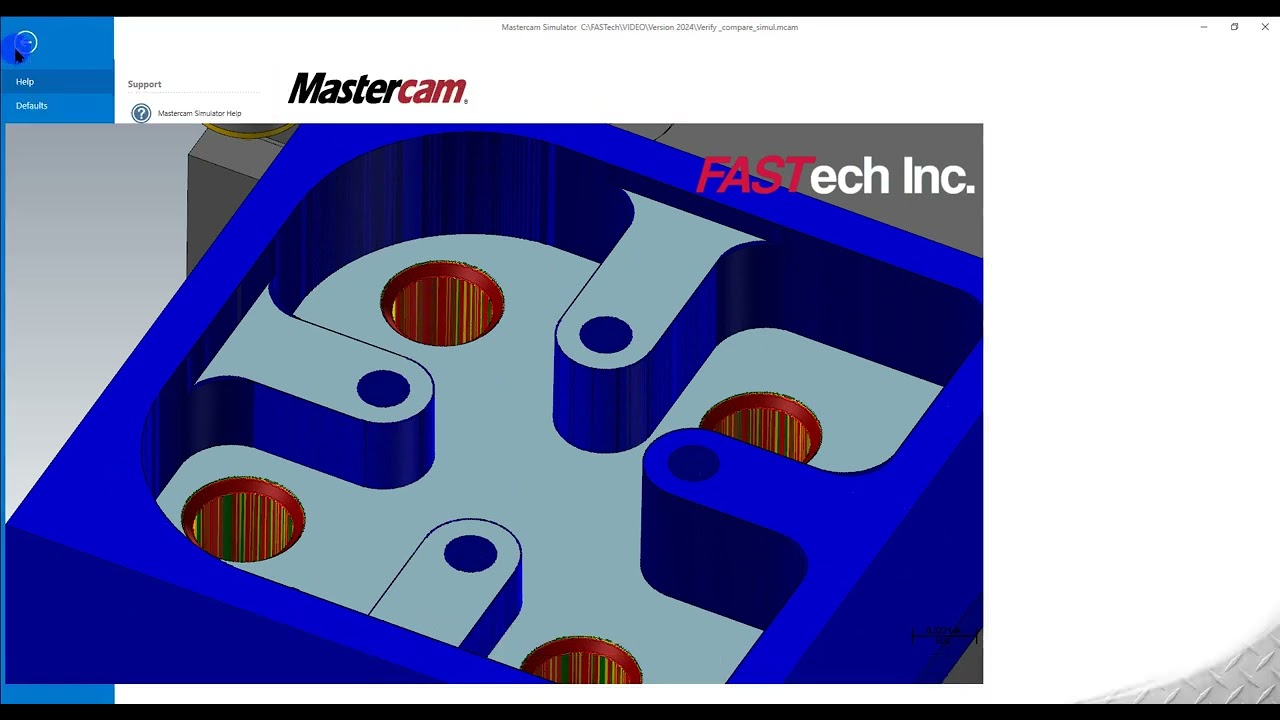

Machine collisions cost time and money. Mastercam includes three levels of verification—Backplot, Verify, and Machine Simulation—that catch problems while they're still virtual.

Backplot provides quick visual confirmation of toolpath motion. Verify adds stock removal visualization and collision checking against holders and fixtures. Machine Simulation models the complete machine tool, including rotary axes and traveling components, to detect issues that simpler verification methods miss.

The NC2Check integration takes verification further by simulating actual G-code rather than toolpath data. This catches post-processor issues and custom macro problems that wouldn't appear in standard verification.

Accelerated Programming Workflows

Traditional CAM programming means writing toolpaths for worst-case scenarios—tight corners, full-slot cuts, heavy engagement. The tool runs conservatively for most of its path just to survive these challenging sections.

Mastercam's Dynamic Motion technology monitors tool engagement throughout the cut and adjusts motion accordingly. The system varies stepover distances and feed rates to maintain optimal chip load, even in corners and pockets where conventional toolpaths would overload the tool.

Shops report material removal rate improvements up to 70% while simultaneously extending tool life. The technology achieves this by keeping cutting forces consistent rather than cycling between light cuts and heavy engagement.

Superior Surface Finish Quality

Finish quality matters for molds, dies, and precision components. Mastercam's multiaxis capabilities position the tool optimally relative to the surface, maintaining proper lead and lag angles that conventional 3-axis toolpaths can't achieve.

The software calculates tool axis orientation dynamically based on surface geometry. Tilt angle limits prevent gouging while ensuring the toolpath respects machine kinematics.

How Mastercam Prevents Costly Machining Errors

The verification environment displays exactly what will happen on the machine. You see stock removal in real-time, watch fixture clearances throughout the operation, and identify any movement that would trigger a limit switch or cause a collision.

Advanced gouge checking monitors the tool-to-part relationship during multiaxis operations. The system establishes a 5-axis safety zone around the geometry and prevents the toolpath from violating it.

This multi-layered approach catches errors that might slip through single-method verification. Post-processor quirks, unusual machine configurations, and complex fixture setups all get validated before you commit to cutting metal.

Universal Machine Compatibility

| Machine Type | Capabilities | Typical Applications |

|---|---|---|

| 2-Axis Milling | Face milling, pocketing, drilling operations | Brackets, plates, simple fixtures |

| 3-Axis Milling | Contour milling, 3D surfacing, complex pockets | Molds, dies, prototype parts |

| 4-Axis Simultaneous | Rotary contouring, wrap-around geometry | Turbine blades, impellers, cams |

| 5-Axis Simultaneous | Complex surfaces, undercuts, optimal tool positioning | Aerospace components, medical implants |

| Mill-Turn | Complete machining in single setup | Shafts, complex turned parts with milled features |

| CNC Router | Nesting, 3D carving, sheet processing | Woodworking, signage, composite parts |

From 2-Axis to Complex 5-Axis

Programming doesn't need to be complicated just because the machine has more axes. Mastercam uses consistent interfaces across all machining types, so moving from 3-axis to 5-axis work feels natural.

The Multiaxis Unified toolpath automatically selects appropriate algorithms based on geometry. You choose surfaces and let the software determine whether geodesic, flowline, or other strategies produce optimal results.

Mill-Turn and Specialty Operations

Mill-turn machines handle complex parts in one setup, but programming them traditionally meant juggling multiple software packages. Mastercam integrates milling and turning operations in a unified environment.

The software manages tool changes, part transfers between spindles, and coordinated simultaneous machining. You program the complete manufacturing process rather than separate operations that need manual coordination.

Seamless Integration With Your Existing Systems

CAD file compatibility determines whether new software disrupts your workflow. Mastercam reads native files from major CAD platforms and maintains associativity with design changes.

When the design team revises geometry, updated toolpaths reflect those changes automatically. This connection between design and manufacturing prevents the miscommunication that leads to scrapped parts.

Universal CAD File Support

Import SolidWorks parts, Inventor assemblies, Creo models, or STEP files with equal reliability. Mastercam's translators handle complex geometry including surfaces, solids, and hybrid models.

The software preserves construction history where possible, allowing you to edit features rather than just faces. This capability proves valuable when fixtures need modifications or designs require manufacturing-driven adjustments.

Automated Toolpath Strategies

Repetitive programming wastes time. Mastercam lets you save proven toolpath strategies and apply them to similar features across different parts.

Feature recognition identifies common patterns—holes, pockets, bosses—and applies appropriate machining strategies automatically. You review and adjust rather than programming from scratch every time.

The CONNECT platform shares toolpath templates, post processors, and machine definitions across your organization. Everyone programs consistently using proven methods rather than reinventing approaches.

Industries and Applications

| Industry | Primary Requirements | Mastercam Advantages |

|---|---|---|

| Aerospace & Defense | Tight tolerances, complex geometries, material traceability | 5-axis capability, rigorous verification, documentation tools |

| Medical Device | Biocompatible materials, intricate features, regulatory compliance | Precision toolpaths, surface quality control, complete audit trails |

| Automotive | High volume, consistency, rapid changes | Automated programming, template libraries, simulation verification |

| Tool & Die | Mold accuracy, surface finish, complex cavities | Advanced surfacing, multiaxis finishing, electrode automation |

| Energy | Large components, hard materials, reliability | Robust toolpaths, simulation validation, mill-turn integration |

| Job Shops | Part variety, quick turnaround, versatility | Universal machine support, rapid programming, flexible workflows |

Job shops benefit from Mastercam's versatility across machine types and part complexity. A single software investment handles diverse work rather than requiring specialized systems for different operations.

Production manufacturers leverage automation features that ensure consistency across shifts and operators. Template-based programming reduces variation and maintains quality standards.

Frequently Asked Questions

What file formats does Mastercam accept?

Mastercam imports SolidWorks, Inventor, CATIA, Creo, Solid Edge, NX, STEP, IGES, Parasolid, and numerous other formats. The software maintains design intent and preserves complex geometry including surfaces and solids.

Can Mastercam prevent machine collisions?

Yes, through multiple verification methods. Mastercam Verify checks tool holder clearance and fixture collisions. Machine Simulation models complete machine kinematics including rotary axes. The NC2Check add-on verifies actual G-code to catch post-processor issues.

Does Mastercam work with my CNC machine?

Mastercam supports virtually all CNC machines through an extensive post-processor library. The software handles mills, lathes, routers, mill-turn centers, wire EDM, and laser systems from all major manufacturers.

How does Mastercam reduce programming time?

Dynamic Motion technology automatically optimizes toolpaths for efficiency. Feature recognition identifies common patterns and applies appropriate strategies. Template libraries let you reuse proven methods across similar parts.

What is Dynamic Motion technology?

Dynamic Motion maintains optimal tool engagement by varying stepover and feed rate based on material conditions. This prevents tool overload in corners while allowing aggressive cutting in open areas, reducing cycle time while extending tool life.

Can Mastercam handle 5-axis machining?

Yes, Mastercam Multiaxis provides simultaneous 4- and 5-axis programming with advanced tool axis control, gouge checking, and collision avoidance. The software manages tilt limits and respects machine kinematics throughout the toolpath.

Manufacturing success depends on reliable programming that produces quality parts efficiently. Mastercam delivers this through intelligent toolpaths, comprehensive simulation, and universal machine compatibility—the complete solution for modern CNC programming.