Buy Geomagic Wrap Software

November 2025 Sale!

Limited time: 5% discount on all products! Ends December 1.

Geomagic Wrap

| Version | Price & Buy |

|---|---|

| 2021 x64 |

What is Geomagic Wrap Software?

When you capture real-world objects with a 3D scanner, the result is typically a collection of points in space—a point cloud. Geomagic Wrap takes this raw data and turns it into clean, watertight models that can be used immediately in downstream applications. Unlike basic scanning software that only captures data, Wrap provides professional-grade editing, surfacing, and refinement tools.

The software handles data from any 3D scanning device or probing system, making it scanner-agnostic. You can import common formats like STL, OBJ, PLY, and XYZ files, then export finished models in industry-standard CAD formats including STEP, IGES, and SOLIDWORKS-compatible files. This flexibility makes Wrap essential for professionals who need to move seamlessly between capture, processing, and production phases.

Industries ranging from aerospace and automotive to entertainment and cultural preservation rely on Geomagic Wrap for digital asset creation. The software excels at handling both organic shapes and geometric forms, making it versatile enough for artistic sculpting projects and precision engineering tasks alike.

How Does Geomagic Wrap Transform Your Workflow?

Traditional scan-to-model processes involve multiple software packages and manual cleanup steps that can take hours or days. Geomagic Wrap consolidates these tasks into a single environment, reducing the time from scan capture to finished model by significant margins.

Accelerated Scan-to-3D Process

The software's mesh processing tools work directly with massive datasets without performance degradation. Projects involving hundreds of individual scans can be merged, aligned, and processed efficiently. Automated hole-filling algorithms detect and repair gaps in scan data, creating watertight models without manual intervention.

Batch processing capabilities handle repetitive tasks across multiple files simultaneously. When you're working with component libraries or product families, scripting functions automate alignment, cleanup, and export operations. This automation turns weeks of manual work into hours of supervised processing.

Seamless CAD Integration

Geomagic Wrap extracts reference geometry directly from scan data—planes, cylinders, spheres, and other primitives that serve as construction references. These features align perfectly with CAD coordinate systems, so when you export cross-sections or surface data to SOLIDWORKS, they drop into place without adjustment. Engineers use these extracted features to create hybrid models that combine scanned organic surfaces with parametric CAD geometry.

The software creates 2D cross-sections at any angle through your scan data. These sections export as editable splines and curves that CAD software can use for lofts, sweeps, and boundary surfaces. You control curve tension, segmentation, and end conditions to match your modeling strategy.

Automation Capabilities

Scripting tools expose over 950 automatable functions within Geomagic Wrap. Quality control departments create custom workflows that inspect parts against nominal geometry, generate deviation reports, and flag out-of-tolerance features automatically. Reverse engineering teams build macros that process entire product catalogs overnight, waking up to cleaned, aligned, and surfaced models ready for CAD reconstruction.

What Makes Geomagic Wrap Ideal for 3D Printing?

Watertight Model Creation

3D printers and slicing software require closed, manifold geometry—models where every edge connects to exactly two faces. Scan data rarely meets this requirement out of the box. Geomagic Wrap's mesh repair tools identify non-manifold edges, flipped normals, and other defects that prevent successful printing. Intelligent hole-filling algorithms match surrounding curvature patterns, creating natural-looking repairs rather than flat patches.

Triangle optimization tools reduce file size while preserving detail in critical areas. You can decimate meshes to specific polygon counts or use curvature-based algorithms that maintain sharp features while simplifying flat regions. This control ensures print files are large enough to capture detail but small enough to process quickly.

Texture Map Management

Color 3D printing requires accurate texture coordinates mapped onto mesh geometry. Geomagic Wrap edits texture maps directly within the software, eliminating roundtrips to image editing programs. You can adjust UV layouts, retouch color information, and preview textured models before printing. This integrated approach saves time for visualization projects, architectural models, and color prototypes.

Direct Manufacturing Output

Models exported from Geomagic Wrap go straight to manufacturing processes including CNC milling, injection molding tool design, and quality inspection workflows. The software maintains geometric accuracy throughout processing, so dimensional checks and tolerance verification stay reliable. Production teams trust Wrap-generated models because they know surface quality and feature accuracy meet manufacturing standards.

Which Industries Benefit from Geomagic Wrap?

- Aerospace engineers reverse-engineer legacy components for replacement part production

- Automotive designers capture clay models and convert them to CAD surfaces for tooling development

- Medical device manufacturers create custom prosthetics and implants from patient scans

- Entertainment studios generate digital doubles and prop replicas for film and gaming

Manufacturing and Engineering

Quality control inspectors compare production parts against design intent by overlaying scan data with CAD models. Geomagic Wrap's deviation analysis tools create color-coded comparison maps showing exactly where parts deviate from specifications. This visual feedback helps identify tooling wear, process drift, and assembly issues before they become costly problems.

Reverse engineering departments face constant pressure to recreate parts without original CAD data. Geomagic Wrap extracts construction features—holes, bosses, ribs, and mounting surfaces—directly from scan geometry. These features become the foundation for parametric CAD models that can be modified and reused for product families.

Design and Entertainment

Character artists scan actors and performers to create realistic digital doubles for visual effects. Geomagic Wrap processes these scans into optimized meshes suitable for animation software like Maya and 3ds Max. Texture editing capabilities ensure that skin tones, clothing, and props maintain color accuracy through the production pipeline.

Product designers use physical prototyping alongside digital modeling. They sculpt foam or clay mockups, scan them, then use Geomagic Wrap to create clean digital versions. This hybrid approach combines the tactile benefits of physical modeling with the precision and flexibility of CAD tools.

Cultural Preservation

Museums and archaeologists document artifacts, monuments, and historical sites using 3D scanning technology. Geomagic Wrap processes these scans into archival models that preserve fine details invisible to photography. Researchers extract cross-sections and measurements from scanned petroglyphs, revealing tooling marks and construction techniques. Educational institutions create 3D-printed replicas that allow students and visitors to handle artifacts safely.

How Does Geomagic Wrap Handle Complex Scan Data?

Large Dataset Management

Long-range scanning projects generate gigabytes of point cloud data covering buildings, landscapes, or industrial facilities. Geomagic Wrap loads and processes these massive files without excessive memory consumption. The software handles thousands of individual scans into unified models, demonstrating its capacity for demanding projects.

The software's viewport rendering maintains interactive frame rates even with dense meshes containing millions of polygons. You can rotate, pan, and zoom fluidly while working, eliminating the lag that slows down editing in other applications.

Multi-Scanner Compatibility

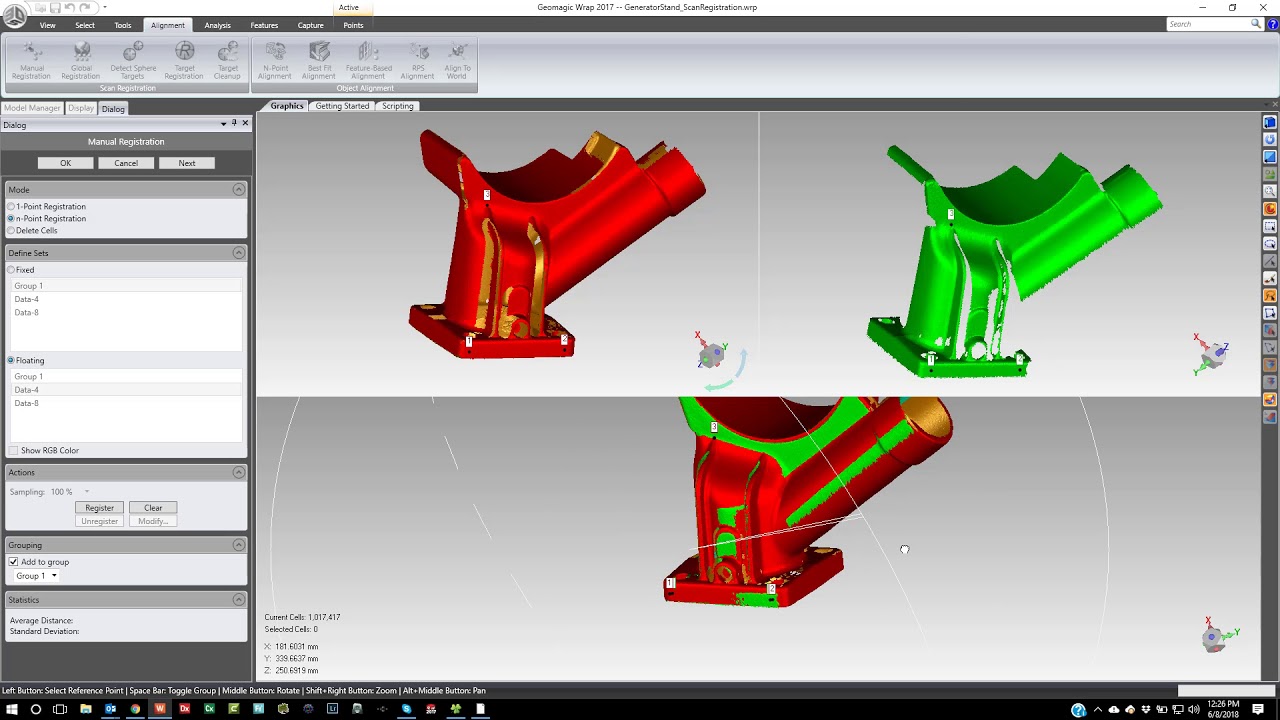

Different scanning technologies produce varying data quality and formats. Structured light scanners capture fine surface detail, while laser rangefinders excel at large-scale environments. Geomagic Wrap imports data from both types seamlessly, allowing you to combine high-resolution detail scans with contextual long-range captures. The software's alignment tools register multiple scans using geometric features or manual reference points.

Advanced Mesh Tools

Remeshing algorithms rebuild scan data with uniform triangle distribution for better surfacing results. You can create quad-dominant meshes that flow naturally around organic forms, or maintain triangulation for engineering applications. Smoothing filters remove scan noise while preserving sharp edges at material boundaries and geometric features.

The polygon healing toolset addresses issues specific to scan data—overlapping geometry, intersecting faces, and inconsistent normal directions. These problems often arise when merging multiple scans or working with reflective surfaces that confuse scanning systems.

What Can You Create with Geomagic Wrap?

NURBS Surface Models

Exact surfacing tools convert polygon meshes into mathematically precise NURBS surfaces suitable for CAD environments. You control patch layout, surface continuity, and edge matching to create models that behave like native CAD geometry. This capability bridges the gap between freeform scan data and parametric design systems.

Automotive stylists appreciate this workflow because it preserves the aesthetic intent of physical clay models while delivering surfaces that meet manufacturing constraints. Surface quality controls ensure G2 continuity where needed for paint finish and aerodynamic performance.

Polygon Meshes

Optimized polygon meshes serve multiple purposes beyond 3D printing. Game developers need low-polygon models that render efficiently in real-time engines. Finite element analysis requires carefully controlled element sizes and shapes. Geomagic Wrap's decimation and remeshing tools create meshes tailored to each application's specific requirements.

Reference Geometry

Extracted features—planes, axes, coordinate systems, and primitive shapes—provide construction references for CAD modeling. Engineers fit cylinders to scanned holes, planes to mounting surfaces, and spheres to ball joints. These fitted features export to CAD software as sketch geometry or construction references, accelerating the modeling process.

Why Choose Geomagic Wrap for Your Projects?

The software consolidates tasks that traditionally require multiple specialized applications. You process raw scan data, edit meshes, extract features, create surfaces, and generate outputs all within one environment. This integration eliminates file conversion errors and maintains data quality throughout your workflow.

| Capability | Business Value | Typical Applications |

|---|---|---|

| Watertight Mesh Creation | Eliminate manual repair steps | 3D printing, manufacturing |

| CAD Feature Extraction | Accelerate reverse engineering | Legacy part recreation |

| Texture Manipulation | Streamline color workflows | Visualization, color printing |

| Workflow Automation | Process large part libraries | Quality control, archiving |

| NURBS Surfacing | Bridge scan-to-CAD gap | Product design, styling |

| Multi-Scanner Support | Equipment flexibility | Cross-platform projects |

The interface presents tools logically, grouping related functions without overwhelming new users. Context-sensitive help and preview modes show operation results before committing changes. This approach reduces the experimentation and error common when learning complex 3D software.

Professional support and extensive documentation help teams implement Geomagic Wrap successfully. The user community shares workflows, scripts, and best practices through forums and video tutorials, providing practical knowledge beyond official documentation.

Frequently Asked Questions

What file formats does Geomagic Wrap support?

Can I use Geomagic Wrap with any 3D scanner?

Yes, Geomagic Wrap works with data from any 3D scanning device or coordinate measuring machine. The software imports standard point cloud and mesh formats regardless of capture hardware. This scanner independence protects your investment if you change scanning equipment or work with data from multiple sources.

How does Geomagic Wrap integrate with CAD software?

Geomagic Wrap exports reference geometry, cross-sections, and surface models in formats compatible with SOLIDWORKS, Inventor, CATIA, and other major CAD platforms. Extracted features align with CAD coordinate systems automatically. Some CAD systems offer dedicated Geomagic plugins that provide deeper integration and direct model transfer within the CAD interface.

What makes Geomagic Wrap different from basic scan software?

While basic scanning software captures 3D data, Geomagic Wrap provides professional editing, repair, and surfacing tools. The software creates watertight models, extracts CAD features, and generates NURBS surfaces—capabilities essential for manufacturing and engineering applications. Automation tools handle batch processing and repetitive tasks that would otherwise require manual work.

Can Geomagic Wrap handle color texture data?

Yes, Geomagic Wrap manages color texture information captured during scanning. The software allows you to edit texture maps, adjust UV coordinates, and prepare models for color 3D printing. This capability supports visualization projects, architectural models, and applications where color accuracy matters.