Purchase Cadsoft Eagle Software

January Sale!

Limited time: 5% discount on all products! Ends February 1.

CadSoft Eagle Professional

| Version | Price & Buy |

|---|---|

| 7.7.0 |

What Is EAGLE PCB Design Software?

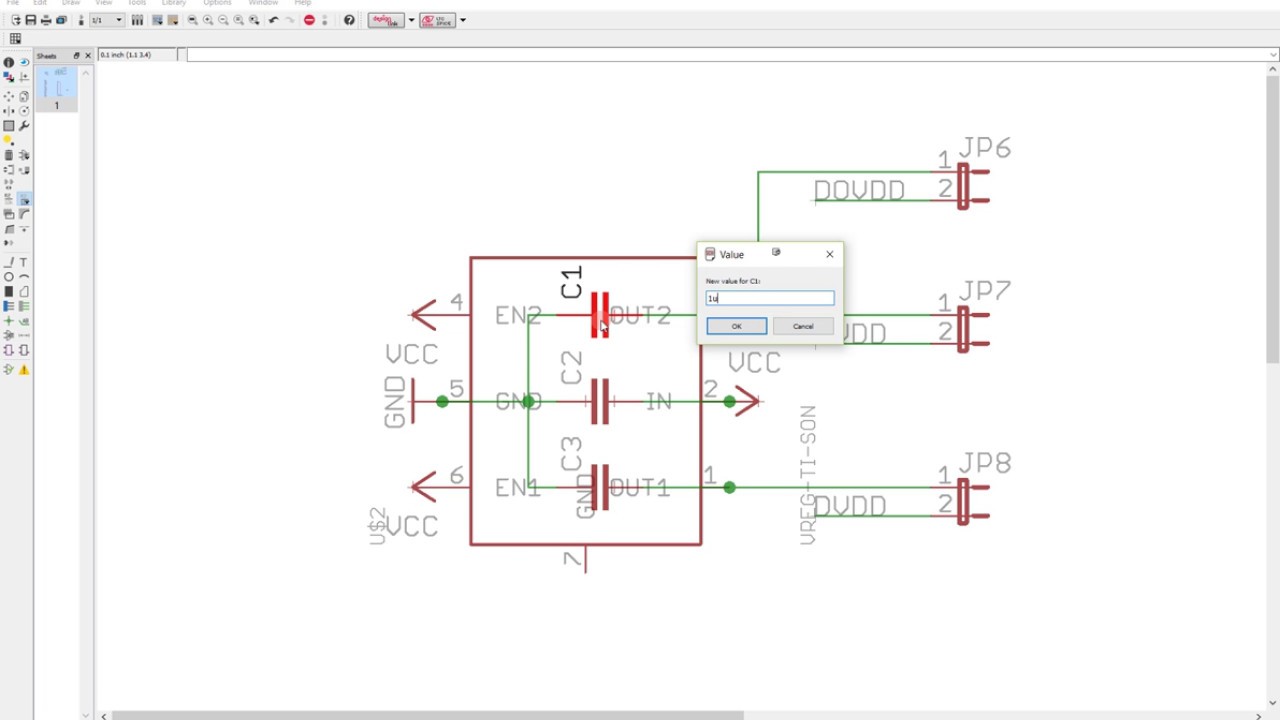

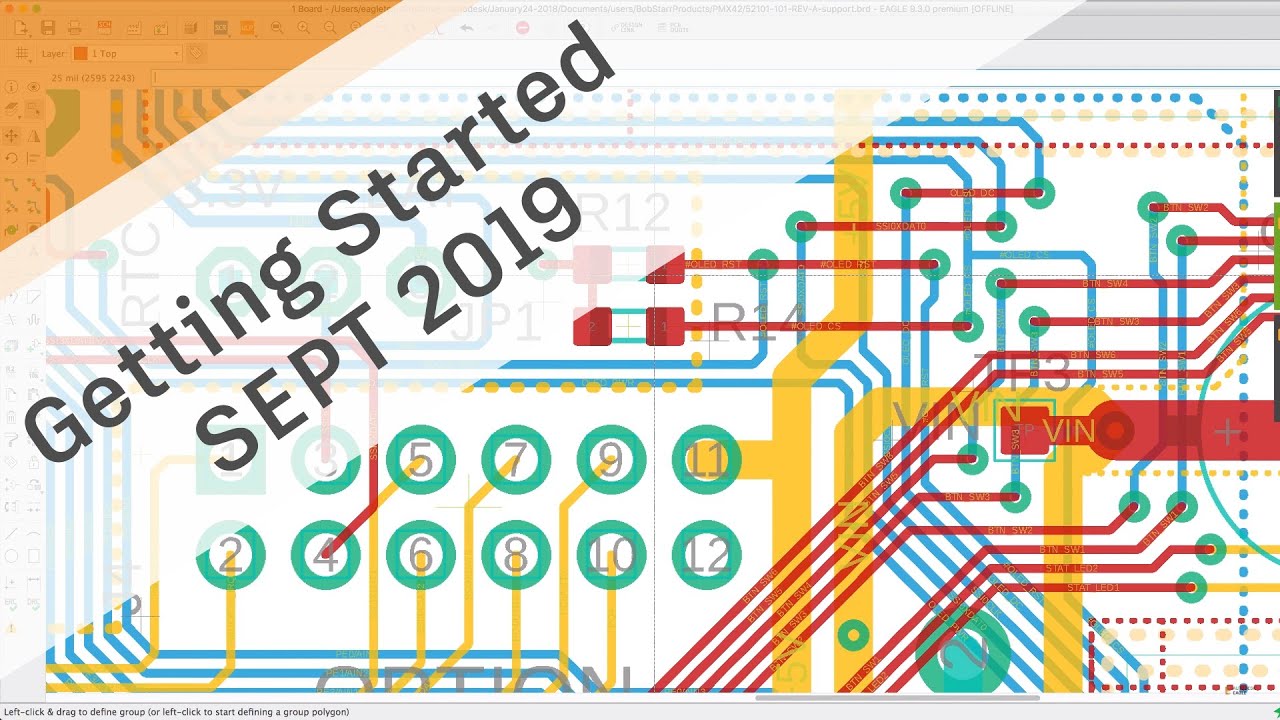

EAGLE connects your schematic diagrams directly to PCB layout within a single workspace, eliminating the file juggling that typically slows down circuit board development. This unified approach means changes made to your schematic automatically update in the layout editor, preventing the synchronization errors that lead to costly board revisions.

The software bridges the gap between circuit design concept and physical board manufacturing, creating a direct path from initial idea to production-ready files. Engineers working on consumer electronics, IoT devices, or industrial control systems use EAGLE to transform electrical concepts into manufacturable circuit boards without switching between disconnected tools.

How Does EAGLE Prevent Costly Design Errors?

Board revisions after manufacturing can drain budgets and delay product launches, making error prevention one of the most valuable aspects of modern PCB design software. EAGLE's validation systems catch problems while designs exist only as digital files, long before expensive physical prototypes reveal issues.

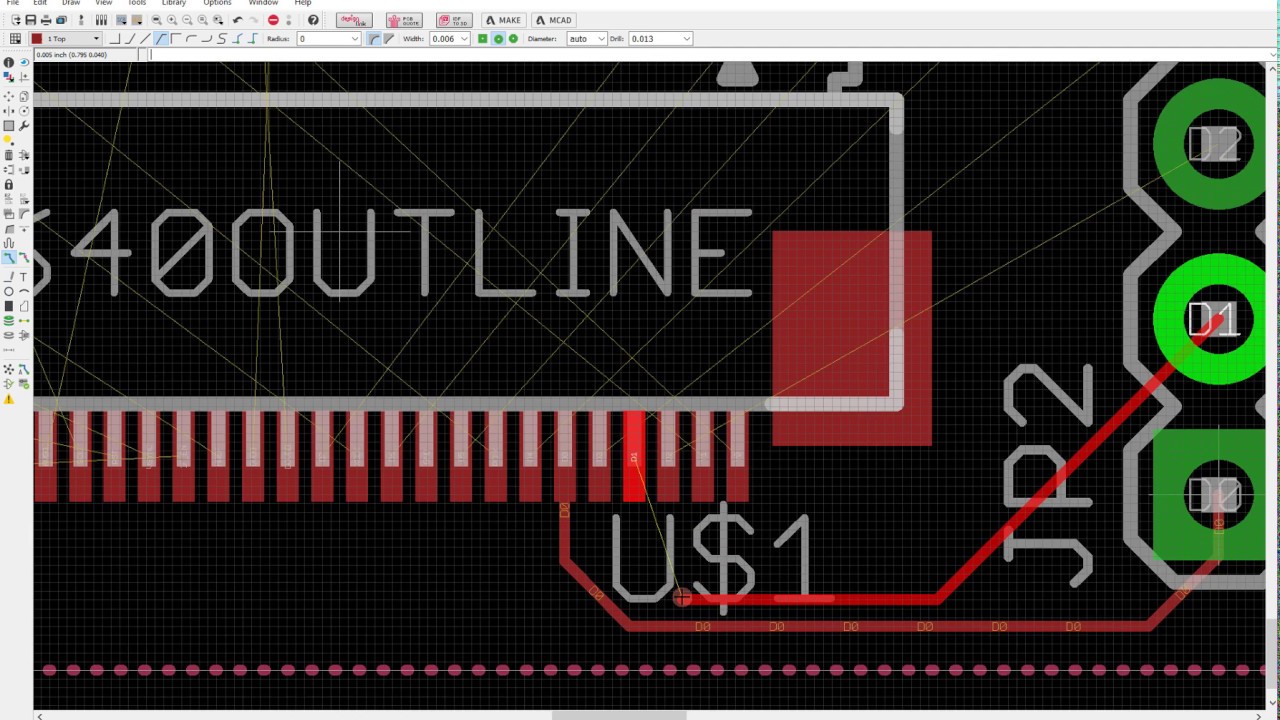

Real-Time Design Rule Checking

The Design Rule Checker continuously validates your layout against manufacturing specifications as you work, flagging potential problems immediately. Trace spacing violations, clearance issues between components, and manufacturing constraints get highlighted before they become production roadblocks.

This real-time feedback loop changes how designers work, transforming error correction from a post-design cleanup task into an ongoing process that prevents problems from propagating through your layout. When a trace gets too close to a via or a component placement violates thermal requirements, you know instantly rather than discovering it during design verification.

Electrical Rule Verification

Beyond physical layout constraints, EAGLE's Electrical Rule Checker examines circuit connections for electrical integrity issues. Unconnected pins, power supply conflicts, and signal path problems get identified automatically, ensuring boards function correctly when powered up for the first time.

The verification engine analyzes your schematic for common circuit errors like floating inputs, conflicting outputs, and missing pull-up resistors. These electrical validation features catch problems that might not become apparent until testing phases, when fixing them requires board respins and schedule adjustments.

What Makes EAGLE Accelerate Your Design Process?

Time-consuming manual tasks represent the hidden costs in circuit board development, where hours spent routing traces or creating component symbols delay project completion. Automation features transform these repetitive activities into quick, system-handled operations.

Auto-Routing Capabilities

Automated routing algorithms handle the tedious work of connecting hundreds or thousands of circuit traces while respecting design constraints. The follow-me routing mode assists manual trace placement by automatically calculating optimal paths as you guide general routing direction.

For complex multi-net routing scenarios, the auto-router analyzes connectivity requirements and generates complete routing solutions that would take days to accomplish manually. Designers maintain control by defining routing priorities, setting critical net constraints, and specifying which sections to route automatically versus manually.

Comprehensive Component Libraries

Pre-built component libraries eliminate hours spent drawing schematic symbols and creating PCB footprints for common parts. Managed libraries provide regularly updated components with verified footprints, reducing the risk of symbol-to-footprint mismatches that cause assembly failures.

When specialized components require custom footprints, the library editor streamlines creation with tools for pad placement, silkscreen generation, and 3D model association. Library management features help teams standardize on preferred parts while maintaining consistency across projects.

| Design Task | Manual Approach | EAGLE Automation | Customer Benefit |

|---|---|---|---|

| Trace Routing | Hand-route each connection individually | Auto-router generates complete solutions | Days of routing work completed in minutes |

| Component Creation | Draw symbols and footprints from scratch | Access managed libraries with verified parts | Start designing immediately without library setup |

| Design Validation | Manual rule checking after completion | Real-time DRC flags issues during design | Catch errors early before they become costly |

| File Generation | Export multiple formats individually | CAM processor creates all outputs together | Consistent manufacturing files every time |

How Does EAGLE Support Professional Manufacturing?

Getting boards fabricated requires translating your design into formats that manufacturing equipment understands, creating a potential translation layer where errors creep in. Direct manufacturing file generation removes this translation step, producing industry-standard outputs that fabricators accept without modification.

Industry-Standard Gerber Export

The integrated CAM processor generates complete Gerber file sets along with drill files, pick-and-place data, and bill of materials in a single operation. These standard formats work with any PCB fabrication house, giving you flexibility to select manufacturers based on capabilities, turnaround time, or pricing rather than file format compatibility.

CAM job configurations save your output preferences, ensuring consistent file generation across multiple design iterations and different projects. When fabricators request specific file naming conventions or format variations, you adjust the CAM job once rather than manually modifying outputs for each design revision.

- Generate complete Gerber RS-274X files with embedded aperture tables for universal compatibility

- Create Excellon drill files with automatic tool assignments and optimization

- Export pick-and-place data for automated assembly equipment with component orientation

- Produce IPC-2581 and ODB++ formats for advanced fabricators using modern data exchange standards

What Design Capabilities Does EAGLE Provide?

Product complexity demands software that handles sophisticated design requirements without forcing workarounds or external tools. Professional-grade capabilities built into the core platform support everything from simple two-layer boards to complex multi-layer designs with controlled impedance routing.

Multi-Layer Board Design

Support for designs with multiple signal and power layers enables compact, high-density layouts where components populate both board sides. Internal power planes reduce noise and improve signal integrity, while blind and buried vias allow routing between specific layer pairs without consuming surface space.

The layer stack manager visualizes board construction, helping you define copper weights, dielectric materials, and impedance targets for high-speed signals. Via management tools handle complex scenarios like BGA escapes where multiple traces must navigate dense pin fields.

3D Visualization Tools

Three-dimensional board visualization reveals component clearance issues before manufacturing, showing where tall capacitors might interfere with connectors or heat sinks. This visual feedback proves especially valuable for designs with mechanical constraints, enclosure fit requirements, or specific component height limitations.

STEP model support enables accurate 3D representations of components, making clearance checking reliable rather than approximate. When mechanical engineers need to verify circuit board fit within product enclosures, the 3D view exports to CAD formats that integrate with mechanical design software.

| Design Requirement | EAGLE Solution | Practical Application |

|---|---|---|

| Compact Board Size | Multi-layer support with blind/buried vias | Fit complex circuits into space-constrained devices |

| High-Speed Signals | Differential pair routing with length matching | USB, Ethernet, and video interface implementation |

| Component Clearance | 3D visualization with STEP models | Verify physical fit before ordering boards |

| Power Distribution | Internal power planes with thermal relief | Reduce noise and improve circuit stability |

How Does EAGLE Enable Team Collaboration?

Distributed teams working across locations need tools that function consistently regardless of individual workstation configurations. Platform flexibility removes technical barriers that can fragment team workflows when different members use different operating systems.

Cross-Platform Compatibility

Native versions for Windows, macOS, and Linux ensure every team member accesses identical functionality without compatibility compromises or virtual machine workarounds. Designers switch between workstations or work from home without encountering platform-specific issues or feature limitations.

Project files maintain complete compatibility across platforms, allowing seamless collaboration where one engineer starts a schematic on Windows, another refines the layout on macOS, and a third performs design verification on Linux. Version control systems track design changes across the team, providing rollback capability when needed and maintaining project history.

Frequently Asked Questions About EAGLE Software

Can EAGLE Import Existing Designs?

Import capabilities support designs from other PCB tools, helping teams transition existing projects without starting from scratch. The software reads common file formats, converting schematics and layouts into native EAGLE format while preserving design intent.

Does EAGLE Support Custom Components?

The component editor provides complete control over custom part creation, from simple resistor symbols to complex integrated circuits with hundreds of pins. User-created libraries integrate seamlessly with standard libraries, enabling teams to build proprietary component collections.

What File Formats Does EAGLE Support?

Beyond standard Gerber and drill files, EAGLE exports IPC-2581, ODB++, PDF documentation, and industry-standard assembly formats. Import support includes common EDA formats, enabling collaboration with partners using different design tools.