Purchase Ansys Electronics Software

January Sale!

Limited time: 5% discount on all products! Ends February 1.

Ansys Electronics/Electromagnetics Suite

| Version | Price & Buy |

|---|---|

| 2024 R2 | |

| 2023 R1 | |

| 2022 R2 | |

| 2021 R2 | |

| 2020 R2 | |

| 2019 R3 x64 | |

| 19.2 x64 | |

| 18.2 x64 | |

| 17.2 x64 (Electromagnetics Suite) |

What Is Ansys Electronics 2024?

Ansys Electronics 2024 is electromagnetic simulation software that helps engineers design and validate electronic systems faster through GPU-accelerated solvers and automated workflows. The 2024 R1 release introduces a redesigned user experience with customizable interface themes, performance improvements up to 50x for multiphysics workflows, and enhanced integration across HFSS, Maxwell, Icepak, and Q3D Extractor solvers.

Engineers working on automotive electronics, consumer devices, aerospace systems, and power electronics use this platform to solve complex electromagnetic compatibility, signal integrity, and RF design challenges. The software targets electrical and electronics engineers who need to predict electromagnetic behavior before physical prototyping.

New in 2024 R1 is a unified interface that removes barriers between different simulation tools, letting teams collaborate without file conversion issues. The release prioritizes practical workflow efficiency over adding complexity, with 12x faster geometry preparation for acoustics analysis and streamlined ECAD-MCAD integration.

How Does Ansys Electronics 2024 Accelerate Your Workflow?

GPU-Accelerated Simulation Performance

The 2024 release brings GPU solver support that delivers 16x faster electromagnetic simulation compared to CPU-only processing. Engineers can run full-wave 3D simulations on affordable graphics hardware, eliminating the need for expensive high-performance computing clusters for most design projects. This performance boost means running ten design iterations in the time previously required for one, fundamentally changing how teams approach electromagnetic optimization.

GPU acceleration extends across multiple physics domains in 2024 R2, with new support for AMD Instinct MI200 and MI300 series hardware alongside existing NVIDIA compatibility. The solver automatically distributes computational work across available GPUs, scaling performance linearly as you add graphics cards. Real-world applications like full-vehicle EMC analysis that once took days now complete in hours, letting automotive engineers test more cable routing scenarios before manufacturing.

Automated Geometry Preparation

Ansys 2024 R1 introduces dedicated acoustics meshing workflows that prepare complex geometries 12x faster than manual methods. The software analyzes your CAD model and generates appropriate mesh densities automatically, removing hours of tedious setup work. Engineers spend less time configuring simulation parameters and more time interpreting results that drive design decisions.

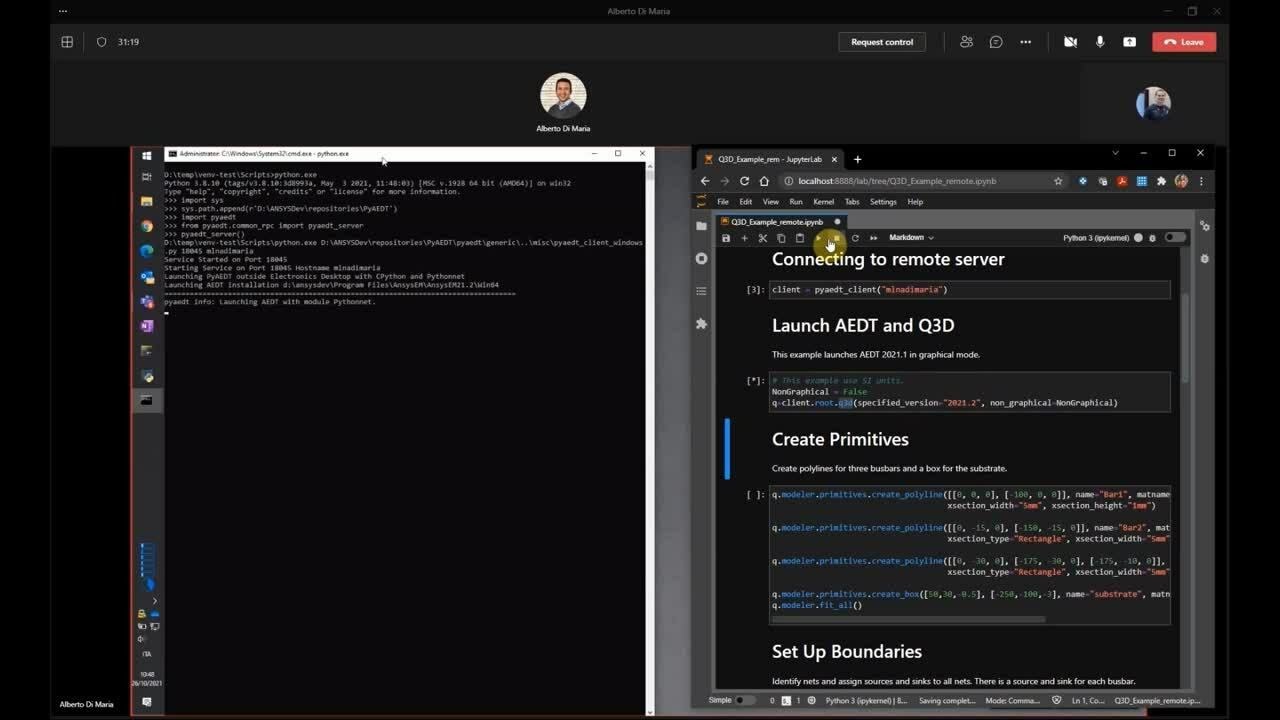

PyAEDT automation capabilities in the 2024 release extend beyond meshing to cover the entire simulation pipeline. You can script geometry creation, material assignment, boundary conditions, solve settings, and post-processing analytics using standard Python syntax. This automation proves valuable when running parametric studies or validating designs across multiple operating conditions, tasks that would otherwise require repetitive manual steps.

What Problems Does Ansys Electronics 2024 Solve?

Electromagnetic Interference Challenges

Full-vehicle electromagnetic compatibility analysis becomes practical in 2024 with automated cable harness integration from KBL wiring diagram files. The software imports your cable database, maps 3D harness routing from mechanical CAD, and sets up EMI simulations without manual connectivity definition. Automotive engineers can evaluate shielding effectiveness, identify coupling paths, and optimize harness routing before building physical prototypes.

New in 2024 R1 is real-time 3D field visualization that reveals electromagnetic hotspots during simulation rather than requiring post-processing. Interactive clipping planes let you inspect electric and magnetic fields inside complex assemblies, immediately identifying problematic coupling mechanisms. This visual feedback accelerates root cause analysis when electromagnetic compliance tests fail, helping teams understand why problems occur rather than just documenting that they exist.

Integration and Collaboration Barriers

The unified interface in Ansys 2024 R1 provides consistent workflows across seven electromagnetic solvers within a single platform. Engineers switch between HFSS for antenna design, Icepak for thermal analysis, and Maxwell for motor simulation using the same menu structures and keyboard shortcuts. This consistency reduces training requirements when team members need to work across multiple physics domains.

Native multiphysics coupling eliminates third-party interfaces that previously created data translation errors. You can map electromagnetic loss densities directly to thermal meshes or export mechanical forces from electromagnetic simulations to structural solvers. The 2024 release handles these cross-physics data transfers automatically, maintaining accuracy while removing manual intervention from coupled analysis workflows.

Which Industries Benefit from Ansys Electronics 2024?

- Automotive Electronics: Full-vehicle EMI/EMC testing with automated cable harness modeling validates electromagnetic compatibility before physical prototyping

- Consumer Electronics: High-frequency RF simulation for smartphones and wireless devices ensures signal integrity and antenna performance across operating bands

- Aerospace and Defense: Electromagnetic environmental effects simulation and RF interference analysis protects mission-critical avionics systems

- Power Electronics: Electric motor design and transformer optimization with automated equivalent circuit generation supports electrification initiatives

- Industrial Equipment: Sensor and actuator electromagnetic design with enhanced thin-layer modeling predicts EMI shielding effectiveness

The 2024 release adds industry-specific workflows that address domain challenges directly. Automotive engineers gain KBL cable import automation, consumer electronics designers get improved ECAD integration, and power electronics teams benefit from enhanced motor design templates. These specialized capabilities reduce the configuration effort required to apply general-purpose electromagnetic solvers to specific industry problems.

Industry Impact: Engineers across automotive, aerospace, consumer electronics, and power electronics sectors use Ansys Electronics 2024 to solve electromagnetic design challenges faster through automated workflows and GPU-accelerated performance.

How Does Python Automation Work in Ansys Electronics 2024?

Complete Simulation Control

PyAEDT in Ansys Electronics 2024 provides programmatic access to every simulation function through standard Python syntax. Unlike earlier scripting methods limited to IronPython, the current implementation uses CPython with access to NumPy, SciPy, and machine learning libraries. Engineers write scripts that create geometries parametrically, assign materials from databases, configure adaptive meshing, run solvers, and extract field data at specific locations.

Custom post-processing becomes straightforward when you can manipulate electromagnetic field data using Python's scientific computing ecosystem. Extract S-parameters, calculate antenna gain patterns, or generate custom plots that match your reporting requirements without being limited to built-in visualization options. The API documentation includes working examples for common tasks, accelerating script development even for engineers new to Python programming.

Automated Cable Harness Modeling

The 2024 release reads KBL wiring diagram files directly and generates 3D electromagnetic models of cable harnesses automatically. The software interprets connector pinouts, wire gauges, shielding configurations, and routing paths from your electrical design database. This automation eliminates manual cable modeling that previously consumed days of engineering time on full-vehicle EMC projects.

Transfer impedance calculations in 2024 evaluate cable shielding effectiveness across frequency ranges automatically. The solver computes coupling between external electromagnetic fields and internal conductors, predicting potential interference with vehicle control modules. Engineers use these results to optimize shielding effectiveness and cable routing before manufacturing prototype harnesses.

What Visualization Capabilities Does Ansys Electronics 2024 Offer?

Real-time 3D field visualization introduced in 2024 R1 displays electromagnetic fields during simulation rather than requiring separate post-processing steps. Watch electric and magnetic field distributions evolve as solvers converge, immediately seeing how design changes affect electromagnetic behavior. Interactive clipping planes slice through complex assemblies, revealing field patterns inside enclosures or between tightly packed components.

The redesigned interface supports three visual modes that reduce eyestrain during extended simulation sessions. Engineers working in varied lighting conditions switch themes without restarting the application. This attention to ergonomics reflects feedback from users who spend entire workdays analyzing electromagnetic simulation results.

| Interface Feature | Benefit | Best Used For |

|---|---|---|

| Dark Mode | Reduces eye strain in low-light environments | Extended simulation sessions and late-night analysis work |

| Light Mode | Improves visibility in bright office settings | Daytime collaboration and presentation environments |

| Classic Mode | Maintains familiar interface for experienced users | Teams transitioning from previous versions |

| Unified Workflow | Consistent operation across all electromagnetic solvers | Multiphysics projects requiring multiple simulation tools |

The Discovery-based visualization engine requires minimal training compared to traditional post-processors. Point-and-click selection of field quantities, automatic scaling for optimal visibility, and intuitive camera controls let engineers focus on interpreting results rather than learning software mechanics. New users typically generate publication-quality field plots within minutes of opening simulation results.

How Does Ansys Electronics 2024 Support Multiphysics Analysis?

Native electromagnetic-thermal-structural coupling in the 2024 release maps simulation results between physics domains without external file transfers. Electromagnetic loss densities become thermal loads automatically, temperature distributions update material properties in electromagnetic solvers, and mechanical forces from electromagnetic actuators drive structural analysis. This bidirectional data exchange maintains consistency across coupled simulations.

Performance improvements in 2024 R1 deliver 5-50x faster execution for noise, vibration, and harshness workflows that combine electromagnetic, acoustic, and structural physics. Optimized memory management and disk space utilization let engineers run multiphysics simulations on workstations that previously required high-performance computing infrastructure. More engineers can tackle multiphysics problems when hardware requirements decrease.

| Multiphysics Capability | Application Example | 2024 R1 Enhancement |

|---|---|---|

| Electromagnetic-Thermal | Power converter thermal management | Automated loss mapping with optimized memory usage |

| Electromagnetic-Structural | Motor vibration and acoustic analysis | 5-50x faster NVH workflow performance |

| Electromagnetic-Circuit | System-level power electronics simulation | Automated equivalent circuit generation |

| Full Multiphysics | Electric vehicle drive unit optimization | Unified interface across all coupled solvers |

Hardware-in-the-loop and software-in-the-loop model export capabilities let you validate electromagnetic designs in system-level simulations. The 2024 release generates reduced-order models from full 3D electromagnetic solutions, providing accurate component behavior for real-time simulation environments. Control engineers use these models to test embedded software against realistic electromagnetic component responses before hardware availability.

Frequently Asked Questions About Ansys Electronics 2024

What types of electromagnetic simulations can Ansys Electronics 2024 perform?

The software handles high-frequency RF and microwave analysis, low-frequency power electromagnetics, signal and power integrity, EMI/EMC compliance, electromechanical device design, and electromagnetic-thermal-structural multiphysics. The 2024 release includes seven integrated solvers covering the full electromagnetic spectrum from DC to light.

Does Ansys Electronics 2024 require specialized hardware?

The software runs on standard engineering workstations with Windows operating systems. GPU acceleration introduced in 2024 works with affordable graphics cards from NVIDIA and AMD, providing 16x performance improvements without expensive computing infrastructure. Most engineers use desktop workstations rather than shared computing clusters.

Can I automate my simulation workflows in Ansys Electronics 2024?

PyAEDT provides complete Python automation from geometry creation through post-processing analytics. The 2024 release uses CPython with access to NumPy, SciPy, and machine learning libraries for advanced custom scripting. Engineers automate repetitive tasks, parametric studies, and custom reporting without being limited to built-in workflows.

How does the 2024 R1 version improve over previous releases?

Key additions include GPU-accelerated solvers with 16x performance gains, real-time 3D field visualization, automated cable harness modeling from KBL files, customizable interface themes (Dark, Light, Classic), 12x faster acoustics meshing, and 5-50x improved multiphysics workflow performance. The release focuses on workflow efficiency rather than adding simulation complexity.

What makes the 2024 interface redesign significant?

The unified interface provides consistent workflows across all electromagnetic solvers within a single platform, reducing training requirements when switching between HFSS, Maxwell, Icepak, and other tools. Three visual modes adapt to different working environments while maintaining familiar menu structures and keyboard shortcuts. This consistency accelerates team collaboration by removing interface learning curves.

Which electromagnetic solvers are included in Ansys Electronics 2024?

The platform integrates HFSS for high-frequency electromagnetic simulation, Maxwell for low-frequency electromagnetics and motor design, Q3D Extractor for parasitic extraction, Icepak for electronics cooling, SIwave for power integrity and signal integrity, and additional specialized solvers for antenna design and electromagnetic compatibility analysis.