Purchase VERO WorkNC Software

January Sale!

Limited time: 5% discount on all products! Ends February 1.

Vero WorkNC x64

| Version | Price & Buy |

|---|---|

| 2024.1 (Hexagon) | |

| 2023.1 | |

| 2021.0 | |

| 2018 R2 | |

| 24.01A |

What is WorkNC?

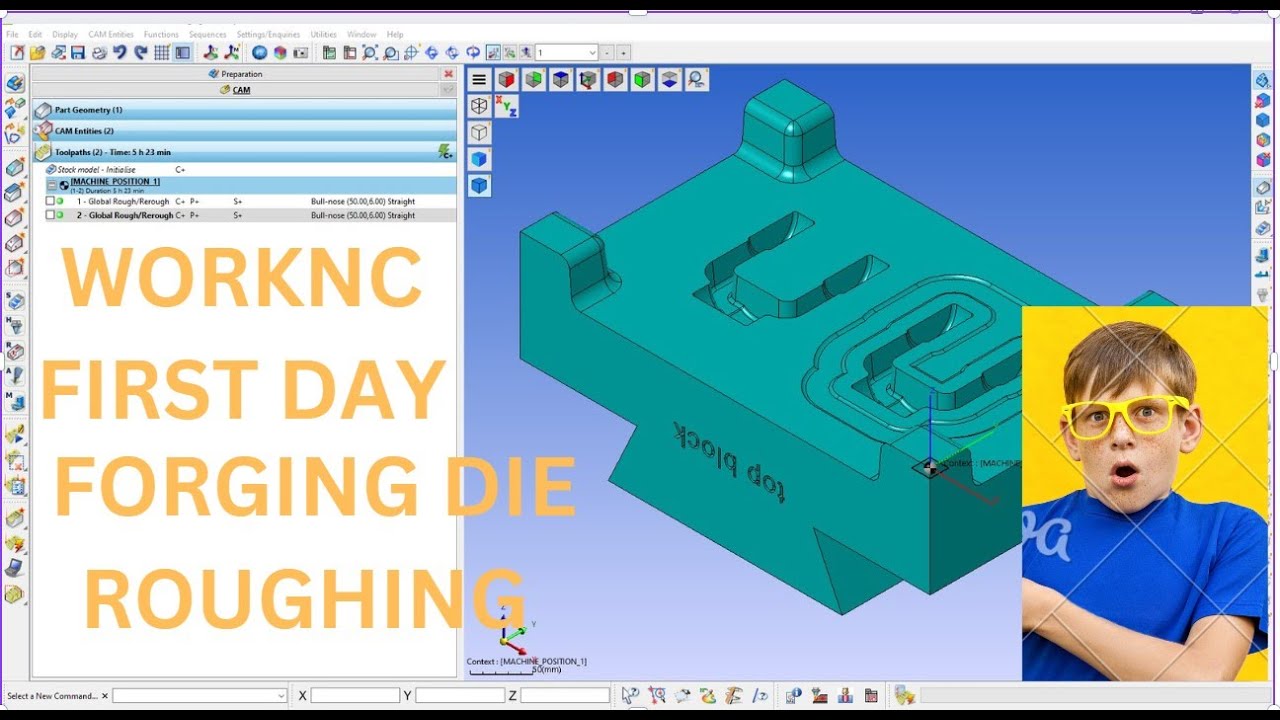

WorkNC is a CAM software for 2 to 5-axis CNC programming designed specifically for mold, die, and tooling manufacturers. Developed by Hexagon (formerly Sescoi), it automates toolpath generation from surface or solid models using advanced algorithms that detect machining zones and optimize cutter paths.

The software targets production machinists, mold makers, and CNC programmers who need reliable automated programming with minimal manual editing. WorkNC is used by automotive OEMs, aerospace manufacturers, medical device producers, and dental prosthetic labs worldwide.

WorkNC operates as standalone CAM software with interfaces to major CAD systems including SolidWorks, CATIA, Siemens NX, and Inventor. It generates machine-ready G-code through customizable post processors for most CNC machines.

Why Buy WorkNC from Prosoftstore?

How Much Does WorkNC Cost?

Official WorkNC 2024 pricing typically starts around $8,000–$10,000 for entry-level 2D/3D packages and scales to $25,000+ for advanced 5-axis configurations, depending on selected modules, post processors, and maintenance contracts. Larger toolroom or enterprise bundles with multiple seats and optional add-ons such as WorkNC-CAD, Dental, or MPM can increase the total investment significantly.

WorkNC Discount Price at Prosoftstore

We offer permanent activation with one-time purchase from $45 to $75 — professional CAM software for 2 to 5-axis CNC programming for production machinists, mold makers, CNC programmers, contract machine shops, and home CNC operators without subscription fees. Full functionality supports mold and die machining, automated toolpath generation, 5-axis simultaneous cutting, and tooling production.

Single payment, lifetime access, no hidden costs or mandatory renewals. Suitable for personal projects, skill development, and running professional-grade machining workflows at home or in small shops that need WorkNC capabilities without OEM-level licensing budgets.

What Does WorkNC Do?

WorkNC creates automated toolpaths for CNC machining operations from 2-axis through full 5-axis simultaneous cutting. The software analyzes 3D models and generates roughing, semi-finishing, and finishing strategies automatically.

- Automatic Feature Recognition: Detects holes, pockets, bosses, and ribs in CAD models and applies pre-defined machining sequences without manual programming.

- Waveform Roughing: Removes material using constant engagement toolpaths that maintain consistent chip load and extend tool life through optimized cutting patterns.

- Dynamic Stock Management: Tracks remaining material after each operation and calculates rest machining automatically to prevent air cutting and collision.

- 5-Axis Simultaneous Machining: Generates continuous 5-axis toolpaths for complex surfaces with automatic collision detection and tool holder verification.

- Parallel Processing: Calculates up to four toolpaths simultaneously using multi-core processors to reduce programming time for complex parts.

- Visual Toolpath Editor: Enables graphical modification of generated toolpaths by drawing boundaries to remove or add material zones without recalculating entire operations.

- Batch Mode Calculation: Processes multiple workzones overnight or during off-hours to prepare complete CNC programs without operator intervention.

- Post Processor Generator: Creates custom post processors for any CNC machine through a template-based system that handles machine-specific G-code formatting.

WorkNC vs Mastercam

WorkNC emphasizes automation and fast learning curves with "one-button CAM" toolpath generation optimized for mold and die work. Mastercam offers broader configurability across diverse machining applications including turning, wire EDM, and mill-turn operations. Choose WorkNC for automated 3D surface milling with minimal programming time in tooling environments.

Where and Who Uses WorkNC?

| Industry/Profession | Application |

|---|---|

| Mold & Die Makers | Programming injection mold cavities, die sets, and forming tools with automated roughing and finishing cycles |

| Automotive Tooling | Creating stamping dies, checking fixtures, and prototype tooling for body panels and interior components |

| Aerospace Manufacturers | Machining turbine blade molds, composite layup tools, and precision fixtures requiring 5-axis continuous paths |

| Medical Device Production | Programming surgical instrument molds, orthopedic implant tooling, and medical device prototypes |

| Dental Laboratories | Milling crowns, bridges, dentures, and implant abutments from zirconia, titanium, and PMMA blanks |

| Contract Machine Shops | Producing complex 3D parts, prototypes, and short-run production using automated CAM programming |

How Can You Use WorkNC at Home?

WorkNC serves home-based CNC operators running desktop or garage-based machining centers for professional-quality work. The software handles complex 3D programming that manual G-code writing cannot achieve efficiently.

- For beginners: Learning automated toolpath generation by programming simple mold inserts or fixture components to develop skills in CAM software operation and machine setup.

- For beginners: Creating basic 3-axis roughing and finishing programs for personal projects while studying WorkNC's automatic feature recognition and stock management systems.

- For advanced users: Programming multi-axis cutting paths for contract work including prototype molds, custom tooling, and small-batch production parts using 3+2 and 5-axis strategies.

- For advanced users: Developing side business machining services for local manufacturers by producing injection mold components, die inserts, and precision fixtures at home.

- For advanced users: Testing advanced parallel processing and batch calculations on complex surface models to optimize programming workflows before scaling up operations.

- For advanced users: Building specialized tooling inventory for resale including vacuum forming molds, rotocasting tools, and composite layup fixtures programmed with automated sequences.

- For advanced users: Fulfilling freelance CAM programming contracts by creating verified toolpaths for clients' parts using WorkNC's simulation and post-processing capabilities.

What's New in WorkNC 2024?

- New toolpath parameters dialog with tabbed layout for faster access to strategy, collision, and cutting settings.

- Updated global roughing algorithms that allow the holder to approach closer to the part while maintaining collision avoidance.

- Parallel finishing strategy consolidated into a unified toolpath with options for tangency extension, stay-on-surface passes, and cross machining.

- Global finishing improvements including flat surface avoidance to skip planar areas automatically during surface finishing.

- Added Rhino CAD file import support and refined management of empty sub-toolpaths for more efficient post-processing.