Purchase VERO AlphaCAM Software

January Sale!

Limited time: 5% discount on all products! Ends February 1.

AlphaCAM

| Version | Price & Buy |

|---|---|

| 2025.1 | |

| 2023.1 | |

| 2020.1 | |

| 2017 R2 | |

| 2016 R1 |

Buy AlphaCAM at cheap prices from $45 to $75. Full version with permanent activation — professional CAD/CAM solution for home workshops, learning CNC operations, and personal routing projects without recurring subscription fees.

AlphaCAM 2025: Professional CAD/CAM Software for CNC Machining and Routing

AlphaCAM 2025 from Hexagon's Manufacturing Intelligence division delivers comprehensive CAD/CAM programming for CNC routers, mills, lathes, and wire EDM machines. The 2025 release introduces workflow enhancements across automation, visualization, and multi-axis toolpath generation.

What's New in AlphaCAM 2025

The AlphaCAM 2025 release cycle brings practical improvements focused on reducing programming time and improving accuracy. Three major updates throughout 2025 added visualization tools, workflow automation, and better file management.

ALPHACAM 2025.1 Enhancements

Version 2025.1 improved solid model rendering with smoother edge visualization and better tolerance handling. Ghost Tools now feature color-coding that matches their related geometries, making toolpath verification more intuitive.

- True-to-Scale Saw Display: Shows accurate saw blade representations including direction indicators and precise cut depth visualization for improved setup verification.

- Aspire V12 Integration: Modernized interface with enhanced 3D CAD tools and reduced mouse travel for cleaner relief modeling and decorative component design.

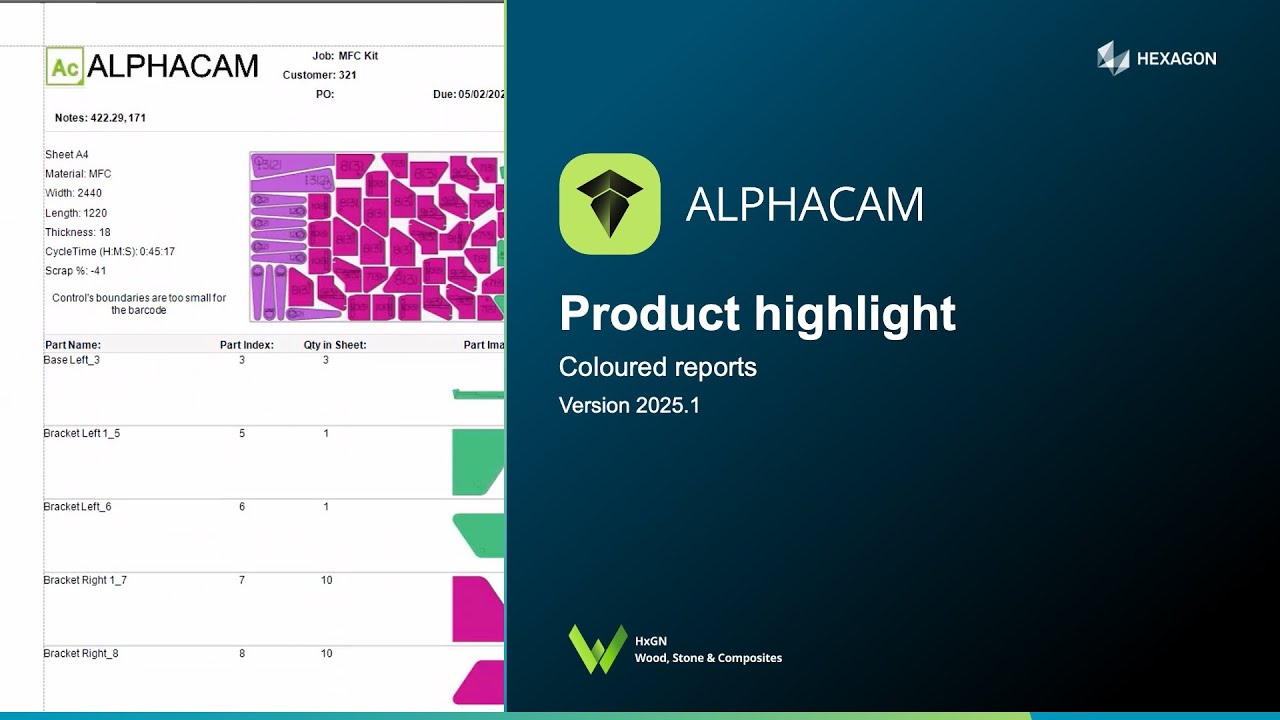

- Color-Filled Reporting: Parts and nested sheets display with color coding for quick component identification and faster layout issue detection.

- Expanded 5-Axis Tooling: Enhanced library with finer multi-axis operation control delivering more accurate simulations for complex machining tasks.

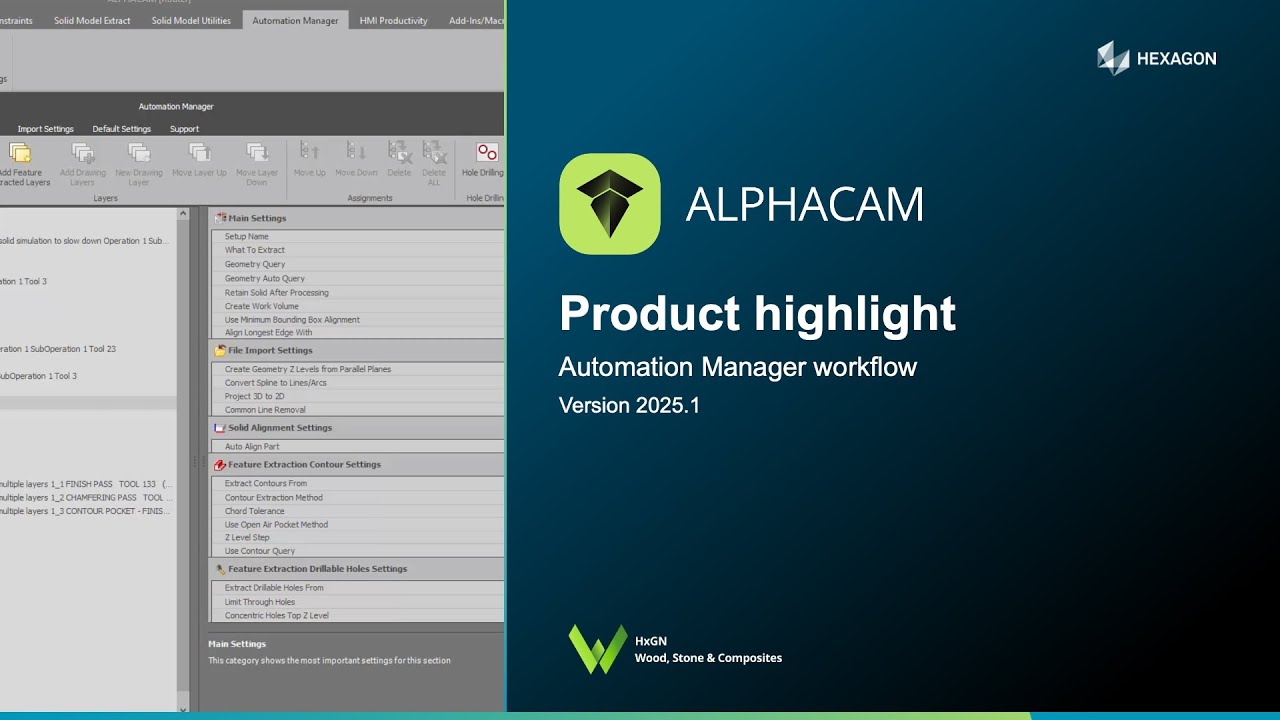

Automation Manager gains diagnostic tools that highlight configuration errors and unused setups.

- Show Missing Machining Styles: Button highlights Layer Mapping Setups with configuration errors, preventing processing failures.

- Highlight Unused Setups: Identifies configurations no longer referenced by active jobs for easier housekeeping.

- Minimum 3D Bounding Box Alignment: Aligns irregular solid parts by longest edge to X or Y-axis, improving nesting material usage.

ALPHACAM 2025.2 and 2025.3 Updates

The 2025.2 release focused on lathe operations and solid simulation capabilities. Pick buttons were added to part-off cycles, facing commands, and approach tabs for faster geometry selection.

- Tool Definition Enhancements: Coolant settings, center-cutting options, and maximum plunge depth parameters establish defaults for pocketing and roughing operations.

- Solid Simulation Compare: Overlays original model against simulated result to verify material removal accuracy.

- Part Visibility Controls: Toggle simulator part display on and off during verification reviews.

- Feature Extraction Improvements: Minimal bounding box alignment and cylinder selection by diameter regardless of plane orientation.

Version 2025.3 highlights: Fast Part Nesting Command streamlines sheet optimization workflows. Enhanced reports now include nested part position images for easier component location on labels and sheet documentation.

Hexagon Universal Updater

AlphaCAM 2025.3 includes the Hexagon Universal Updater, simplifying software maintenance. The updater notifies users about new releases and provides direct access to documentation and forums.

- Automatic Installation: Downloads new versions and initiates installation process automatically when updates become available.

- Local Caching: Stores installation media under program data for faster reinstalls when needed.

- Application Launcher: Launch installed Hexagon applications directly from the updater interface.

- Optional File Management: Copy additional installation package files to local storage through the updater.

Core CAD/CAM Capabilities

AlphaCAM provides integrated CAD design and CAM programming within a unified environment. The software handles geometry creation, file import from external CAD systems, and toolpath generation for multiple machining processes.

Integrated CAD Design Tools

The core geometry toolkit includes standard drawing commands for lines, arcs, circles, rectangles, polygons, ellipses, splines, and polylines. Intelligent snapping captures endpoints, midpoints, centers, intersections, tangents, and quadrants during design work.

- Editing Functions: Move, copy, rotate, mirror, scale, break, trim, explode, join, extend, fillet, chamfer, and offset operations with unlimited undo/redo.

- Organization Tools: Multi-layer and multi-origin control organizes complex drawings with multiple components or assemblies.

- AlphaCAM Designer: Direct modeling lets users push, pull, and drag geometry without modifying parameter histories, speeding design iterations.

- Model Healing: Automatically closes small gaps between surfaces during import, reducing manual repair work on external CAD files.

CAD File Import and Compatibility

The software reads DXF and DWG files for 2D geometry along with IGES format for surfaces and solids. Native CAD translators support Catia V4/V5, Pro/ENGINEER, PTC Creo, Autodesk Inventor, Siemens NX, SolidWorks, Solid Edge, and SketchUp.

| File Type | Supported Formats | Primary Use |

|---|---|---|

| 2D CAD | DXF, DWG, AI, PostScript | Profile routing, nesting, engraving |

| Surface Models | IGES, STEP, Parasolid | 3D machining, surface finishing |

| Native CAD | CATIA, Creo, Inventor, NX, SolidWorks | Feature extraction, solid machining |

| Mesh/STL | STL, OBJ | Artistic routing, relief carving |

Batch import processes multiple DXF files simultaneously while maintaining associativity with imported solid models for feature recognition.

Parametric Sketcher and Geometry Creation

The Parametric Sketcher creates dimension-driven profiles where geometric relationships maintain design intent during modifications. Changes to one dimension automatically update related geometry.

- Comment Fields: Version 2025.2 added documentation capabilities for design decisions and dimension purposes directly within sketch definitions.

- Formulas and Expressions: Support for calculated relationships between parameters in dimension fields.

- Toolpath Integration: Sketch profiles export cleanly to machining operations with proper constraint handling preserved.

Routing and Woodworking Features

AlphaCAM serves as a total solution for the woodworking industry from small custom joinery shops to large production facilities. The Router modules include tooling and machining techniques specific to wood, composites, and sheet goods processing.

Industry standard positioning: Dedicated routing capabilities make AlphaCAM the go-to solution for programming CNC routers with specialized workflows for grain direction control, spoilboard management, and vacuum hold-down considerations.

2D and 3D Routing Operations

Standard 2D routing covers profile cutting, pocketing, drilling, and engraving operations with automatic lead-in and lead-out generation. Corner cutting includes straight, roll-round, or loop approaches based on tool diameter and material characteristics.

- Tool Compensation: G41/G42 support maintains accurate part dimensions regardless of cutter wear or diameter variations.

- 3D Strategies: Multiple roughing and finishing strategies handle surfaces, STL mesh models, and native CAD solids on any work plane.

- Waveform Roughing: Optimizes material removal rates while maintaining consistent tool engagement for longer cutter life and better surface quality.

- Horizontal Aggregates: Standard operations for hinge reliefs and lock mortices can be saved and inserted onto work planes, reducing repetitive programming.

Horizontal Aggregates and Special Tooling

Horizontal aggregates available on most CNC routers receive full programming support for machining hinge pockets, lock mortices, and edge profiles perpendicular to the main cutting plane. Standard aggregate operations can be created once, saved to libraries, and recalled for similar features.

- Rotary Axis Support: Aggregates with programmable rotary axes and manual tilt angles are fully supported along with complete 5-axis interpolation heads.

- Coordinate Transformations: Software generates appropriate transformations and approach moves for aggregate positioning.

- Collision Checking: Includes aggregate body geometry to prevent interference with fixtures, clamps, or workpiece during operation.

Cabinet and Furniture Manufacturing

Cabinet production workflows benefit from AlphaCAM Art, combining Vectric's Aspire design software with AlphaCAM manufacturing capabilities. This solution handles 3D relief modeling for decorative panels, doors, and custom millwork.

- Artistic Integration: Provides design tools with production-ready toolpath generation in a single package for decorative woodworking.

- Casebuilder Integration: CABINET VISION order entry and manufacturing software defines cabinet construction including face frame, frameless, and 32mm styles.

- Assembly Automation: Assembly sheets and batch export to AlphaCAM streamline the path from order to production for cabinet shops.

Multi-Axis Machining Capabilities

AlphaCAM handles indexed and simultaneous multi-axis machining for routers, mills, and turn-mill centers. Work plane support simplifies 4-axis and 5-axis indexed operations where cutting occurs in standard 2D or 3D modes after rotating the part.

4-Axis and 5-Axis Indexed Machining

Work plane functionality defines machining operations on any oriented surface of a part. Components can be dragged and dropped onto fixture representations with datum points set visually.

- Sequence Optimization: Software automatically optimizes machining sequences across multiple work planes to minimize repositioning and reduce cycle time.

- Collision Detection: Checks tool holder and spindle geometry against fixtures throughout the toolpath to prevent crashes.

- Work Coordinate Tracking: Manages position shifts between setups automatically with proper post processor support.

| Machining Mode | Axis Configuration | Typical Applications |

|---|---|---|

| 3-Axis Standard | XYZ linear | Profile milling, pocketing, surface machining |

| 3+2 Indexed | XYZ + rotary positioning | Five-sided machining, angled drilling |

| 4-Axis Simultaneous | XYZ + continuous A or C | Cylinders, cams, wrapped geometry |

| 5-Axis Simultaneous | XYZ + continuous dual rotary | Turbine blades, complex surfaces, undercuts |

Advanced 5-Axis Simultaneous Machining

The Advanced 5-Axis module integrates continuous multi-axis cutting strategies within the standard machining environment. Strategies maintain optimum tool-to-part contact throughout the cut, improving surface finish and extending tool life.

- Multi-Surface Finishing: Controls lead and lag angles plus side tilt for ball mills and tapered cutters across multiple surfaces.

- Profile Machining: Handles slotting, de-flashing, and trimming of sheet-formed components in 5-axis mode.

- Specialized Tools: Full support for lollipop cutters enables machining of deep pockets and undercut features impossible with standard end mills.

- Collision Avoidance: Automatically applies necessary tilts to move tool and holder geometry away from potential crash zones.

SWARF Milling and Profile Cutting

SWARF cutting (Side Wall Axial Relief Feed) drives the tool side along variable-taper walls common in aerospace components. The tool tilt follows surface wall angle while tool lift is controlled by base surfaces or bounding curves.

- Five-Axis Curve Operations: Runs tool once along path with axis parallel to drive surface, excelling at de-flashing molded parts and trimming composite layups.

- Blend-Between Strategy: Machines fillet surfaces by starting parallel to one curve and finishing parallel to another, ideal for complex transition zones.

- Turn Milling: Uses 4-axis rotary attachments on mills to produce turned shafts using milling cutters, combining mill and lathe operations.

Large movement control: Toolpath features manage large machine movements from small component cuts, preventing damage through collision avoidance algorithms and holder geometry checking throughout cutting sequences.

Automation Manager and Workflow Optimization

Automation Manager eliminates repetitive manual programming by batch processing CAD files from import through NC code generation. The system applies pre-defined tooling and machining strategies automatically based on layer mapping rules and feature recognition.

Batch Processing and File Automation

Files can be imported directly from 2D CAD, 3D CAD, or CSV data sources with automatic feature extraction and toolpath application. The system processes each file without manual intervention from geometry insertion through NC code and report generation.

- Multi-Select Processing: Version 2025.2 added CTRL+click selection of specific parts or CDM doors, enabling partial job runs and iterative programming.

- Report Automation: Batch process creates complete report structures including part labels and bar coding for full traceability.

- CSV Import: Links directly to order management systems, pulling part lists with quantities and material specifications for automated nest generation.

- Layer Mapping: Configurations define which geometry layers receive which machining operations based on color coding and line types.

Layer Mapping and Machining Style Management

Layer mapping setups assign machining styles to geometry layers, automating the connection between CAD layers and manufacturing operations. Version 2025.1 added the ability to highlight unused setups for easier housekeeping.

- Bulk Editing: Select multiple layers simultaneously for efficient configuration updates.

- Missing Styles Detection: Button expands tree view and highlights all layer mappings pointing to non-existent machining style files, preventing processing errors.

- Dependency Tracking: When deleting setups, system displays which jobs reference them, allowing dependency modification before removal.

Multi-Select and Part Alignment Tools

Part-level rotation alignment applies specific angles to individual parts, overriding default rotation methods for that component. This proves useful when parts perform better at fixed orientations due to grain direction or machining sequence requirements.

Minimum 3D Bounding Box Alignment: Calculates smallest rectangular boundary around irregular solid parts and aligns longest edge to X or Y-axis, improving nesting density and material utilization for asymmetric components automatically.

For Home Users, Learners, and Hobby Projects

AlphaCAM offers multiple entry points for individuals building CNC skills or running small-scale production operations. The software scales from basic 2D work through advanced multi-axis capabilities, allowing users to grow into more complex features over time.

Pay-once structure advantage: Hobbyists and students invest in software that remains functional as long as needed without recurring fees that can burden personal projects or learning exercises.

Software Editions for Different Skill Levels

AlphaCAM Essential provides the entry level for basic 2D CNC work including profile routing, drilling, and simple pocketing operations. Users can start with Essential and upgrade as skills and project complexity increase.

| Edition | Best For | Key Capabilities |

|---|---|---|

| Essential | Beginners, 2D work | Profile routing, drilling, basic pockets |

| Standard | Small shops, 3D basics | Surface machining, work planes, nesting |

| Advanced | Complex surfaces | Free-form finishing, advanced strategies |

| Ultimate | Multi-axis work | Full 4/5-axis simultaneous machining |

Learning CAM Programming with AlphaCAM

The software's operational style interface reduces the learning curve by presenting machining options in logical sequences. Visual feedback shows toolpath results immediately after strategy selection.

- Solid Simulation: Lets learners verify programming decisions before running jobs on actual machines, reducing material waste and machine time.

- Post Processor Libraries: Extensive libraries mean students can program for virtually any CNC controller, building transferable skills.

- Unlimited Undo: Software tolerance for experimentation encourages learning through trial and error without consequences.

- Template System: Files and standard operations can be saved and reused, establishing best practices as users develop programming expertise.

Small Shop and Personal CNC Projects

Personal CNC router owners benefit from AlphaCAM's nesting capabilities that maximize material yield from sheet goods. The software handles grain direction requirements and supports small batch production through kit nesting.

- Report Generation: Part labels help organize components during assembly even in single-person operations.

- AlphaCAM Art Integration: Opens decorative carving and relief modeling to hobbyists without extensive CAD training through 3D clipart and mesh model imports.

- Creative Applications: Pay-once alternative for makers pursuing decorative panels, custom signs, and gift items without ongoing subscription costs.

Nesting and Material Optimization

Automatic nesting functionality arranges parts on sheet materials to maximize yield and minimize waste. The nesting engine achieves best-in-class material utilization with users reporting gains up to 20% compared to older systems.

Automatic Nesting and Sheet Optimization

The nesting algorithm handles part orientation with options to fix rotation when grain direction matters or allow any-angle rotation for maximum density. Tool lead-in and lead-out paths are accommodated during placement to ensure adequate approach space.

- Support Tags: Small part tagging prevents loss of vacuum hold-down on router tables with porous spoilboards.

- Multiple Depth Cuts: Supported when onion-skin approach is required for thick materials or delicate parts.

- Operation Ordering: System orders operations by type and optimizes tool sequences to minimize changes.

- Common Cut Removal: Recognizes when multiple parts share an edge, eliminating redundant cutting and reducing cycle time while improving edge quality.

Custom reporting provides complete traceability from nest layouts through individual part labels with optional bar coding.

Kit Nesting and Grouped Production

Kit nesting keeps related parts grouped on the same sheet because they make up a complete unit or assembly. This organization simplifies downstream handling by ensuring all components for one cabinet, door set, or assembly are cut together.

- Color Coding: Reports show which kit each part belongs to, preventing mixing during production.

- Material Flexibility: Parts within a kit can have different materials or thicknesses as long as nesting rules accommodate the variations.

- Make-to-Order Support: Each job may have unique specifications but remains tracked as a complete unit throughout the process.

Fast Part Nesting Command: Introduced in 2025.3, this feature speeds up sheet optimization with streamlined controls that reduce the number of clicks required for standard nesting tasks.

Quick Nest Enhancements in 2025.3

The 2025.3 release refined nesting workflows with the Fast Part Nesting Command that accelerates sheet optimization tasks. The command maintains all underlying nesting intelligence while presenting a simplified interface for routine operations.

- Nested Part Position Images: Added to reports to help locate where each component sits on the sheet, useful for part identification labels.

- Visual Reference: Speeds up part retrieval from nested sheets during assembly operations.

- Label Integration: Position data integrates with label printing systems for automated identification tag application directly on components.

Simulation, Verification, and Reporting

Solid simulation builds a virtual representation of the machining process including material removal, tool holder clearance, and machine kinematics. This verification catches programming errors before they reach the shop floor, preventing crashes and scrap.

Solid Simulation and Collision Detection

The solid simulator displays the full machine build including spindles, tool changers, rotary axes, fixtures, and workholding. Tool holders are checked continuously for collisions with clamps, fixtures, and workpiece throughout the toolpath.

- Compare Function: Version 2025.2 added overlay of original CAD model against simulated result to verify material removal accuracy.

- Show Simulator Part Toggle: Controls part visibility during simulation review, letting users focus on toolpath motion or switch to part detail as needed.

- Cross-Section Views: Enhanced part visibility helps analyze internal feature machining and verify pocket depths, hole drilling, and thread mill positioning.

- Interactive Playback: Speed control lets users step through problematic sections slowly while running through verified portions at full speed.

Enhanced Reporting with Color Visualization

Reports in AlphaCAM 2025.1 now feature filled color images for parts and nested sheets, making visual cross-referencing significantly easier. Parts receive distinct colors for quick location on sheet layouts when referencing part lists.

- Color Continuity: Coding carries through to all documentation including assembly instructions and cutting sequences.

- Kit Visualization: Nesting displays parts grouped by color according to kit membership for immediate component identification.

- Error Reduction: Colored visualization reduces errors caused by part misidentification and speeds up quality control reviews of nesting layouts.

Part Position Tracking and Labels

Nested part position images show exactly where each component sits on the source sheet with coordinate references. This information appears in both sheet reports and individual part labels.

- Operator Verification: Machine operators use position references to verify correct part extraction from nested sheets, especially with multiple similar components.

- Bar Code Support: Label generation supports bar coding for automated tracking through assembly and finishing departments.

- Custom Templates: Report engine accommodates simple part identification tags through complete job summary reports with material usage, cycle times, and tool lists.