Buy InventorCAM Software

October 2025 Sale!

Limited time: 5% discount on all products! Ends November 1.

InventorCAM for Autodesk Inventor

| Version | Price & Buy |

|---|---|

| 2025 SP2 (Inventor 2018-2025) | |

| 2024 SP3 (Inventor 2018-2025) | |

| 2023 SP3 (Inventor 2018-2025) | |

| 2022 SP3 (Inventor 2018-2023) | |

| 2021 SP5 (Inventor 2018-2022) | |

| 2020 SP4 (Inventor 2018-2021) | |

| 2019 SP2 (Inventor 2012-2020) | |

| 2018 SP2 (Inventor 2012-2019) | |

| 2017 SP2 (Inventor 2012-2018) | |

| 2016 SP3 HF1 (Inventor 2012-2018) | |

| 2015 SP2 HF3 (Inventor 2012-2016) | |

| 2014 SP4 (Inventor 2012-2015) |

What Is InventorCAM Software and How Does It Work?

Unlike standalone CAM systems that require constant file exporting and importing, InventorCAM works within the familiar Inventor interface. You define machining operations, verify toolpaths, and generate CNC code while your design remains fully editable in the same workspace.

The software supports the complete manufacturing workflow from initial setup through post-processing. Machine definitions, stock models, and fixture arrangements all exist within the Inventor assembly environment, making it simple to visualize and verify complete machining setups before sending code to the shop floor.

What Are the Key Benefits of Using InventorCAM?

InventorCAM delivers measurable improvements in both programming speed and machine efficiency. The integrated workflow eliminates the context switching that slows down traditional CAD-to-CAM processes.

- Work in a single software environment without exporting files or managing version conflicts between CAD and CAM systems

- Automatic toolpath regeneration when designs change saves hours of manual reprogramming work

- Direct access to Inventor assembly features means fixtures, workholding, and machine components are visible during programming

- Reduced programming time through automated calculation of optimal machining parameters

iMachining Technology Advantages

The iMachining module represents a different approach to material removal. Instead of following traditional machining practices, it uses patented algorithms to maintain constant tool load throughout the cutting cycle.

Real-world implementations have documented cycle time reductions ranging from 60% to 80% compared to conventional programming methods. A manufacturer in China reduced machining time from 4 hours to 58 minutes—a 75% improvement—by switching to iMachining 3D. Another company achieved 63% cutting time reduction on production parts.

The Technology Wizard automatically calculates optimal feeds and speeds based on your specific combination of tool material, workpiece material, and machine capabilities. This removes the guesswork from setting cutting parameters and ensures consistent results across different operators.

Automatic Toolpath Updates

Full associativity between CAD geometry and machining operations means design revisions don't require starting over. When you modify an Inventor model, InventorCAM marks affected toolpaths for regeneration rather than deletion.

All operation parameters—tool selections, cutting depths, geometry references—persist through model changes. Click regenerate and the software recalculates toolpaths based on the updated geometry while maintaining your original machining strategy.

What Can You Create with InventorCAM?

The software handles diverse manufacturing requirements across multiple industries. Shops producing aerospace components use InventorCAM for complex 5-axis parts, while job shops rely on it for rapid programming of short-run production work.

| Manufacturing Application | InventorCAM Capabilities | Key Advantage |

|---|---|---|

| Mold Making | 3D roughing and finishing strategies with automatic rest machining | Reduced cycle times through intelligent Z-level optimization |

| Prismatic Parts | Automatic pocket recognition and multi-feature machining | Single operation programs entire part from solid model |

| Rotational Components | Turning, facing, grooving, and threading operations | Combined mill-turn programming in one environment |

| Complex Surfaces | Multi-axis contouring, swarf, and tilt machining | Simultaneous 4 and 5-axis toolpaths for intricate geometries |

Milling Applications

InventorCAM covers the full range of milling operations from simple 2D pockets to complex 5-axis surface machining. The adaptive clearing strategy excels at removing large volumes of material efficiently while maintaining tool life.

For 3D work, the software combines roughing and finishing strategies that minimize non-cutting movements. Intelligent step-up algorithms and localized machining eliminate unnecessary retracts and positioning moves that waste cycle time.

Turning and Mill-Turn Operations

Shops with turning centers or mill-turn machines can program complete parts without switching software packages. Standard turning operations like facing, grooving, and boring work alongside milling operations in synchronized programs.

The mill-turn functionality supports both live tooling and sub-spindle operations. Secondary setups reference the stock condition left by primary operations, ensuring accurate material removal calculations.

How Does InventorCAM Integrate with Autodesk Inventor?

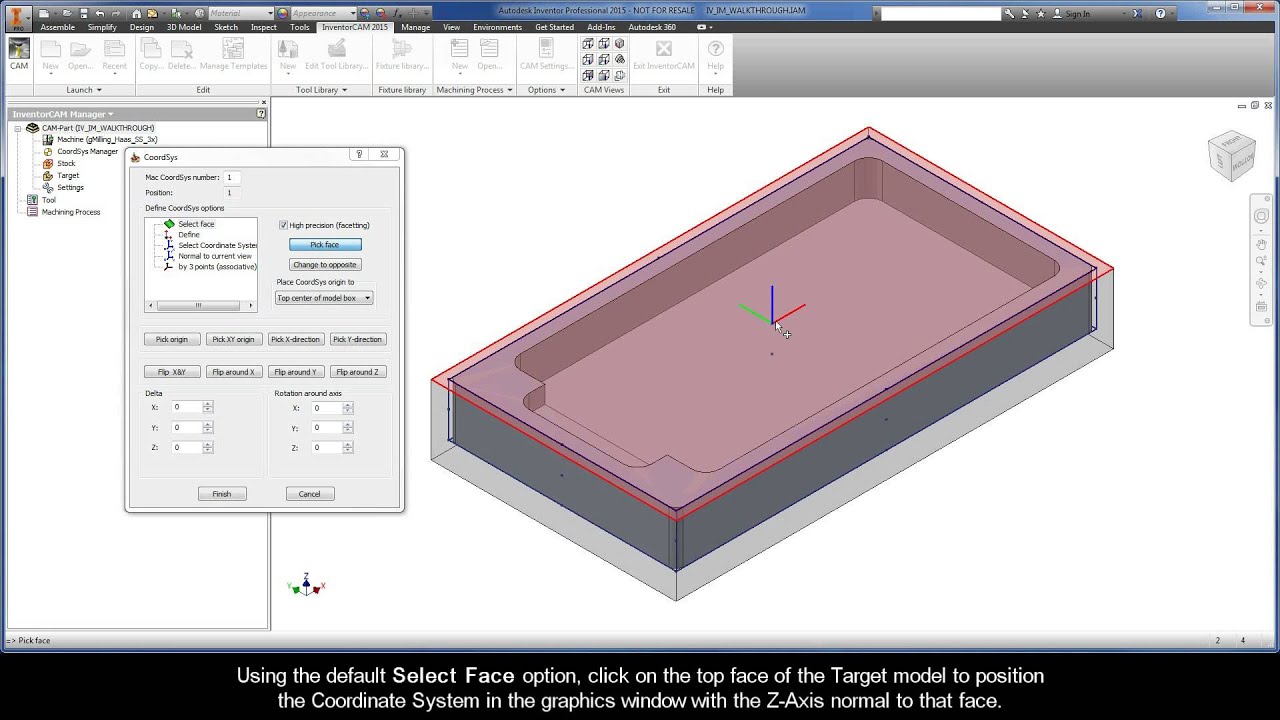

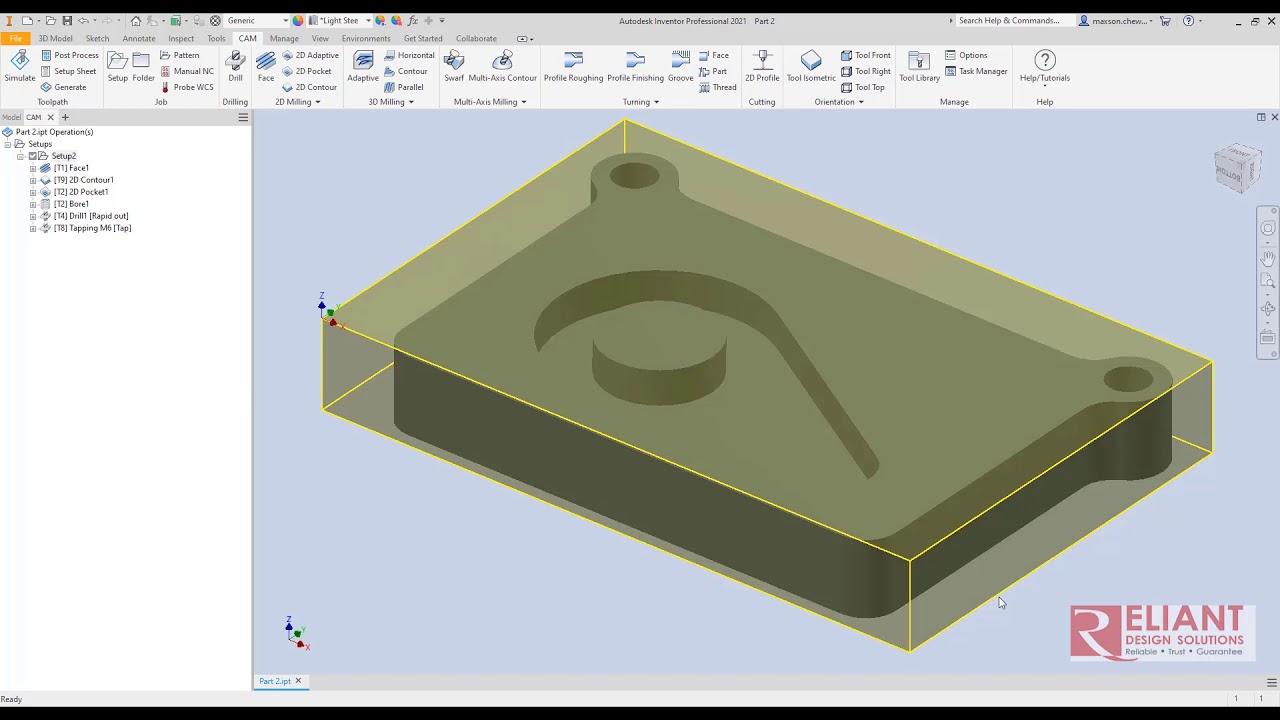

InventorCAM appears as an additional ribbon tab within Inventor's interface. All machining commands are accessible through familiar Inventor-style panels and dialogs.

The CAM Browser replaces Inventor's Model Browser when machining operations are active, displaying setups, operations, and toolpaths in a hierarchical tree structure. Right-click menus and context-sensitive commands follow Inventor's established patterns, reducing the adjustment period for existing Inventor users.

Geometry selection uses Inventor's native selection tools. Pick faces, edges, or solid bodies directly from the graphics window using the same methods you use for modeling operations.

Handling Design Changes

The associativity system tracks relationships between CAD features and machining operations. When you modify a sketch or feature that affects programmed geometry, InventorCAM flags dependent operations with a regeneration indicator.

Regeneration typically takes seconds for 2D operations and completes in the background for 3D strategies, allowing you to continue working while toolpaths recalculate. The Task Manager shows calculation progress and can be minimized if lengthy 3D toolpaths are processing.

What Machining Capabilities Does InventorCAM Provide?

The software scales from basic 2-axis milling through complete 5-axis simultaneous machining. Multi-axis capabilities include rotary positioning, indexed 4-axis machining, and continuous 5-axis contouring.

- 2.5-axis milling for pockets, contours, and drilling operations with automatic feature recognition

- 3-axis strategies including adaptive clearing, parallel finishing, and steep-and-shallow toolpaths

- 4-axis rotary machining with automatic indexing and wrapping of 2D toolpaths onto cylindrical surfaces

- 5-axis simultaneous contouring for complex sculptured surfaces and turbine blade geometries

- Turning operations with live tooling support for complete mill-turn programming

- Swiss-type machining with coordinated main and sub-spindle operations

Adaptive Clearing Strategy

The strategy works by calculating optimal tool engagement at every point along the toolpath. When the tool enters open areas, stepover increases to remove material quickly. In tight corners where engagement would otherwise spike, the algorithm reduces stepover to maintain safe cutting forces.

Benefits extend beyond faster cycle times. Consistent chip loading means predictable tool wear, allowing shops to maximize tool life and reduce replacement costs. Better chip evacuation from the smooth, trochoidal tool motion also improves surface finish on roughed parts.

Multi-Axis Machining

Complex geometries that once required specialized CAM systems are now accessible within the Inventor environment. Simultaneous 5-axis toolpaths handle undercuts, complex surfaces, and parts that can't be efficiently machined with 3-axis strategies.

Multi-axis operations include specialized strategies for different geometries: swarf machining for ruled surfaces, multi-axis contouring for free-form shapes, and tilt machining for features at compound angles. Automatic collision detection checks tool holder and machine components throughout the toolpath.

How to Get Started with InventorCAM?

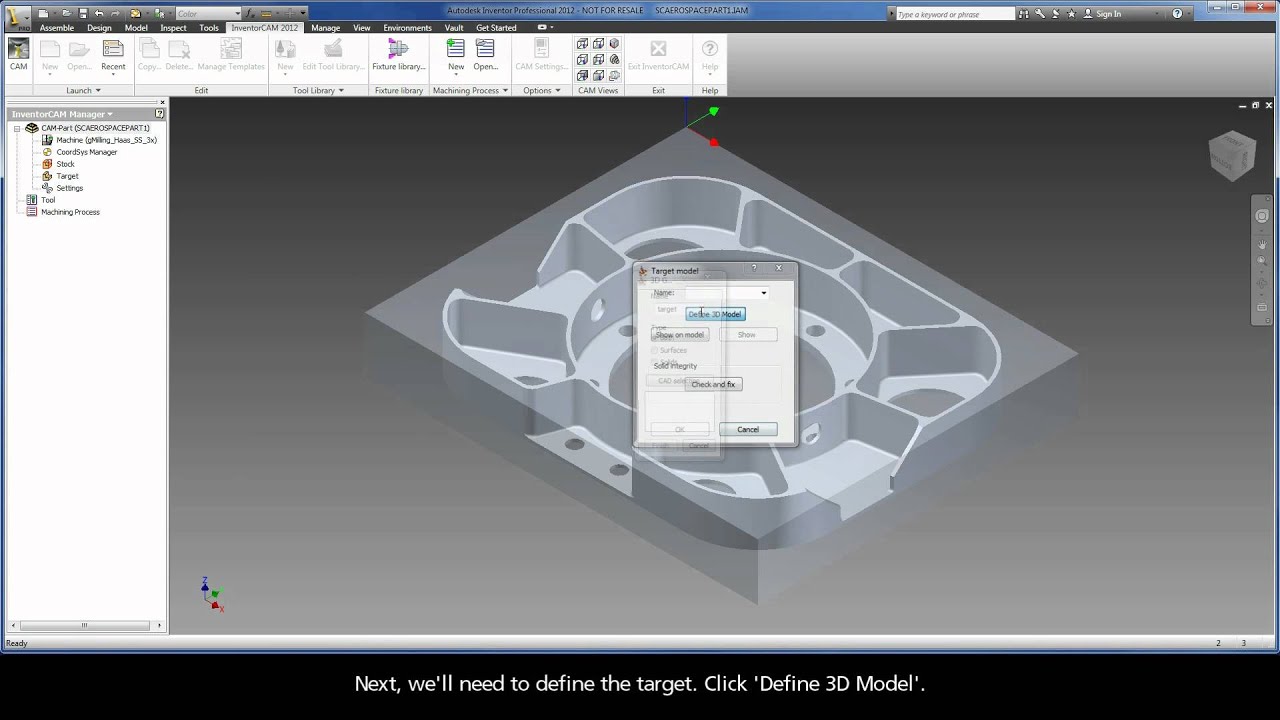

Implementation begins with defining machine configurations that match your shop equipment. The software includes templates for common machine types—3-axis mills, 4-axis horizontal machining centers, turning centers, and mill-turn machines.

Post processors convert toolpaths into machine-specific G-code. InventorCAM ships with customizable post processors for major CNC control brands. An online library provides additional posts for specialized machines and older controllers.

The typical workflow starts by opening an Inventor part or assembly and activating the CAM environment. Define your setup by specifying the machine type, stock dimensions, and work coordinate system orientation. Select appropriate machining strategies from the ribbon, define geometry and cutting parameters, then simulate and verify toolpaths before generating CNC code.

Frequently Asked Questions About InventorCAM

Does InventorCAM require exporting files from Inventor?

No. InventorCAM operates directly within Inventor's interface, eliminating file export and import steps. All machining operations reference the live Inventor model.

What happens to toolpaths when I change my design?

Toolpaths maintain associativity with the model and flag for regeneration when affected geometry changes. Parameters and selections persist—you simply regenerate rather than reprogram.

Can InventorCAM handle both milling and turning?

Yes. The software includes complete capabilities for milling, turning, and combined mill-turn operations. Program entire mill-turn parts in a single setup.

How does iMachining reduce cycle times?

iMachining maintains constant tool load through intelligent stepover control, allowing higher feed rates and deeper cuts than conventional methods. The Technology Wizard automatically calculates optimal parameters.

What types of CNC machines does InventorCAM support?

The software supports 2.5-axis through 5-axis mills, turning centers, mill-turn machines, and Swiss-type lathes. Customizable post processors generate code for major CNC control brands.

Does adaptive clearing work with all materials?

Adaptive clearing effectively machines aluminum, steel, stainless steel, and other common materials. The constant load approach particularly benefits hard materials and small diameter tools.

Can I program secondary operations after initial machining?

Yes. InventorCAM can save stock bodies at any machining stage for use in subsequent setups. This enables accurate programming of secondary operations that reference partially machined stock.