Purchase PTC Creo Software

January Sale!

Limited time: 5% discount on all products! Ends February 1.

PTC Creo 12.4

64bit

$75.00

PTC Mathcad Prime 10.0

64bit

$75.00

PTC Creo + HelpCenter

| Version | Price & Buy |

|---|---|

| 12.4.2.0 | |

| 11.0.5.0 | |

| 10.0.9.0 | |

| 9.0.11.0 | |

| 8.0.12.0 | |

| 7.0.12.0 | |

| 6.0.6.0 | |

| 5.0.6.0 | |

| 4.0 M150 | |

| 3.0 M190 (x32+x64) | |

| 2.0 M250 (x32+x64) | |

| 1.0 M050 (without HelpCenter) |

What Is PTC Creo Parametric CAD Software?

The software handles the complete product development cycle without requiring data export to separate programs for analysis or manufacturing preparation. When you modify a design in Creo, those changes automatically propagate through related drawings, assemblies, and documentation. This eliminates the manual updating that consumes hours when using disconnected design tools.

Creo originated as Pro/ENGINEER, the first commercial parametric CAD system introduced in the 1980s. PTC has continuously evolved the platform to incorporate modern capabilities like real-time simulation, augmented reality visualization, and AI-driven automation while maintaining backward compatibility with legacy design data.

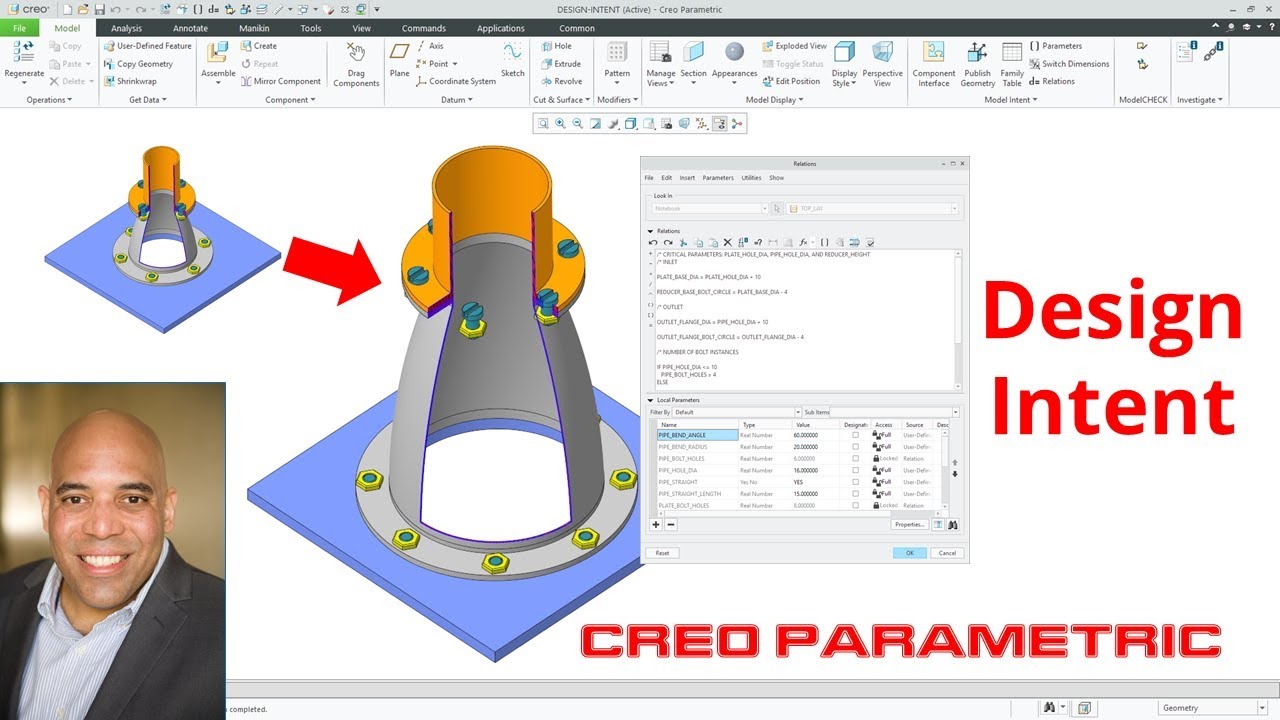

Parametric and Direct Modeling in One Platform

Most CAD software forces you to choose between parametric modeling or direct modeling approaches. Creo provides both methods in the same workspace, letting you switch techniques based on what the situation requires. Parametric modeling captures design intent through dimensional relationships and constraints, making it ideal for products that need systematic updates across variations. When a supplier requests a last-minute mounting hole relocation, parametric features ensure the change maintains proper spacing and alignment automatically.

Direct modeling removes those constraints for quick geometry manipulation. This approach works well when you're incorporating supplier-provided components or making urgent modifications where speed matters more than maintaining extensive edit history. The flexibility to use either method on the same design gives you options that purely parametric or purely direct systems can't match.

Complete CAD/CAM/CAE Integration

Creo includes computer-aided manufacturing and engineering analysis capabilities that share the same 3D model foundation. You can generate CNC toolpaths directly from your part geometry or run structural simulations without exporting files to separate applications. This integration eliminates the data translation errors that occur when moving models between disconnected software packages.

The platform also connects with PTC's Windchill PLM system for enterprise data management and ThingWorx for IoT integration. These connections enable manufacturers to track how products perform in the field and feed that information back into design improvements.

What Are the Key Benefits of Using Creo?

Handle Planned and Unplanned Design Changes

Design modifications often arrive late in development when tooling decisions are already underway. Creo's parametric foundation lets you accommodate these changes without rebuilding models from scratch. The software maintains relationships between features, so adjusting one dimension automatically updates dependent geometry throughout the assembly.

The direct modeling tools complement this by allowing quick edits to imported geometry or legacy designs where the original parametric structure isn't available. You can pull, push, and reshape surfaces directly, then convert those changes to parametric features if needed for future control. This dual capability means you're never stuck reworking an entire model because of a single specification change.

Reduce Prototype Costs Through Virtual Testing

Physical prototypes can cost thousands of dollars and weeks of waiting for each iteration. Creo Simulation Live runs structural, thermal, and modal analysis directly inside the design window as you work. The software displays stress concentrations and deformation patterns in real-time while you're sketching and modeling, catching potential failures before you commit to manufacturing.

This immediate feedback helps you identify issues during initial design rather than discovering problems after building expensive prototypes. You can test multiple design alternatives virtually in hours instead of waiting weeks for physical samples. Many engineering teams reduce prototype iterations significantly by catching design flaws early through simulation.

Accelerate Design Workflows with Automation

Creo automates repetitive tasks that traditionally consume significant engineering time. The software generates 2D production drawings automatically from 3D models, creating views, sections, and dimensions based on industry standards. When you update the 3D geometry, drawings refresh automatically to reflect those changes.

Generative design tools use AI algorithms to create optimized geometry based on your specified loads, materials, and manufacturing constraints. Instead of manually iterating through design variations, you define the requirements and let the software explore hundreds of alternatives to find solutions that meet performance targets while minimizing weight or material usage.

| Design Approach | Best Used For | Key Advantage |

|---|---|---|

| Parametric Modeling | Product families with controlled variations | Maintains design intent through changes |

| Direct Modeling | Quick modifications and imported geometry | Fast edits without constraint dependencies |

| Hybrid Approach | Complex projects requiring both methods | Flexibility to choose optimal technique per task |

How Does Creo Handle Multi-CAD Collaboration?

Work Directly with SolidWorks, CATIA, and NX Files

Creo Unite Technology opens native files from other major CAD systems without converting them to neutral formats. You can incorporate SolidWorks parts, CATIA assemblies, or Siemens NX components directly into your Creo designs while preserving their original features and configurations. The imported models appear as editable geometry that you can modify using Creo's direct modeling tools.

This capability eliminates the file conversion process that typically introduces errors and loses design intelligence. When your supplier updates their component file, Creo detects the change and offers to refresh your assembly with the latest version. The system maintains assembly relationships and constraints even though the components originated in different CAD platforms.

Seamless Collaboration with External Partners

Manufacturing projects typically involve multiple companies using different design software. Creo's multi-CAD support means you don't need to mandate specific software across your supply chain or spend time converting files between formats. Suppliers can continue using their preferred tools while you work with their designs natively.

The software supports industry-standard neutral formats like STEP and IGES when working with partners outside the major CAD platforms. Creo maintains geometric accuracy and can import metadata like material properties and manufacturing notes embedded in these exchange files.

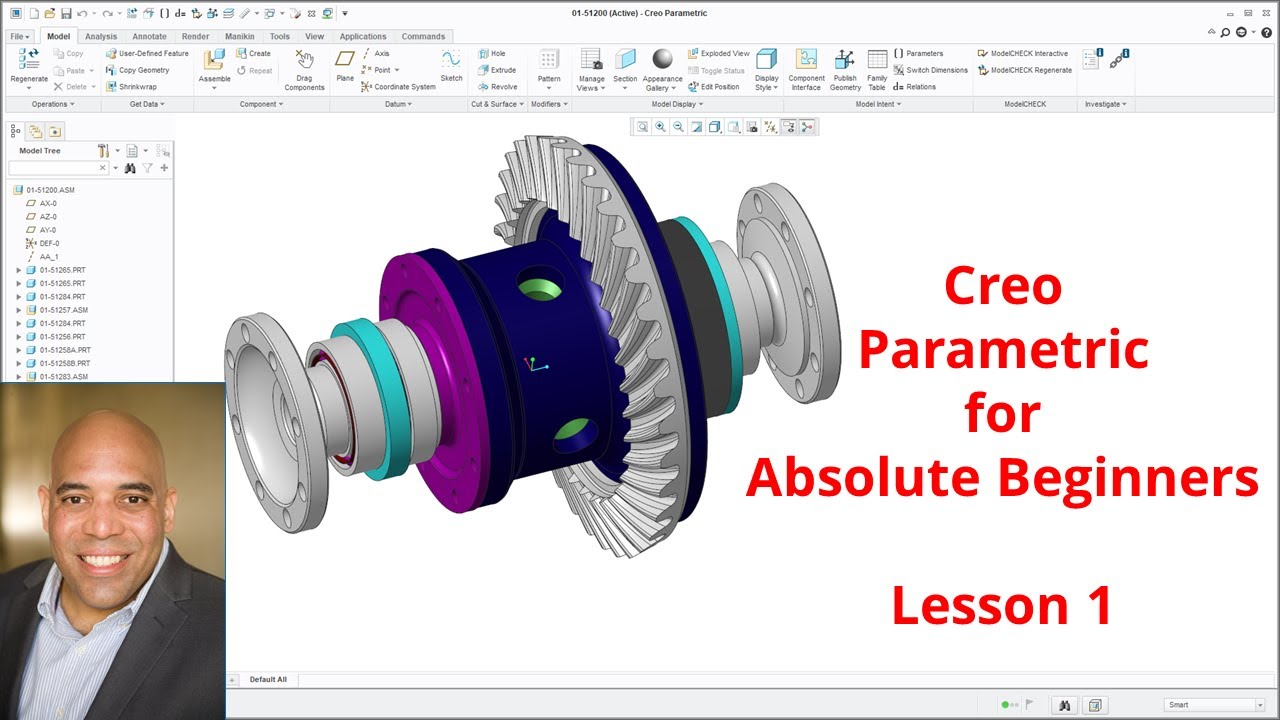

What Can You Design with Creo Parametric?

From Simple Parts to Complex Assemblies

Creo handles individual components like machined brackets or injection-molded housings as easily as it manages assemblies with tens of thousands of parts. The software includes specialized tools for sheet metal design, piping and cabling layouts, plastic part design with draft analysis, and additive manufacturing optimization.

Large assembly performance remains responsive even when working with highly detailed models. Creo loads components on-demand and uses lightweight representations where full detail isn't necessary, keeping system performance smooth while providing access to complete geometry when you need it.

Applications Across Multiple Industries

- Aerospace companies design aircraft components and assemblies requiring precise weight control and structural validation

- Automotive manufacturers develop vehicle systems from individual fasteners to complete body-in-white structures

- Medical device firms create implants and surgical instruments with complex organic geometries

- Industrial equipment producers engineer machinery ranging from hand tools to heavy construction equipment

- Consumer electronics teams develop products where packaging constraints and aesthetic surfacing are critical

- Defense contractors create specialized equipment requiring extensive documentation and configuration management

How Does Creo Improve Design Validation?

Instant Feedback with Creo Simulation Live

Traditional simulation requires exporting your design, creating a mesh, defining boundary conditions, running the analysis, and interpreting results. Creo Simulation Live provides immediate visual feedback while you're actively modeling. As you adjust a rib thickness or modify a mounting location, the software shows updated stress patterns and deformation within seconds.

This real-time analysis helps you understand how design decisions affect performance without interrupting your workflow. You can quickly compare alternatives by making changes and observing the immediate structural response. The instant feedback loop accelerates the design optimization process that would normally require hours of setup and analysis time.

Test Designs Before Manufacturing

Beyond real-time simulation, Creo includes advanced analysis capabilities for detailed validation. You can perform finite element analysis for structural integrity, computational fluid dynamics for airflow and cooling, and motion analysis for mechanism behavior. These tools help identify potential failures or performance issues before committing to tooling or production.

Virtual prototyping also enables testing conditions that would be difficult or expensive to recreate physically. You can simulate extreme temperatures, high-cycle fatigue loading, or unusual environmental conditions to understand product behavior across the full range of operating scenarios.

How to Get Started with Creo Parametric?

Integration with Existing Workflows

Creo works alongside existing design data through its multi-CAD capabilities. You can begin using Creo for new projects while continuing to access and modify legacy designs created in other systems. The software reads common file formats and can serve as a universal viewer for designs across your organization's history.

The platform connects with standard PDM and PLM systems for data management, letting you maintain established workflows for design review, approval processes, and release procedures. Creo also offers API access for custom automation and integration with in-house tools.

Solutions for Teams of All Sizes

Creo serves individual designers through enterprise deployments with thousands of seats. The same software and file formats work across all licensing levels, enabling seamless collaboration between small suppliers and large manufacturers. This compatibility ensures that design data flows smoothly regardless of company size or licensing tier.

The modular structure lets you start with core 3D modeling capabilities and add specialized extensions as your needs grow. Extensions cover areas like advanced surfacing, mechanism design, composite materials, and specific industry applications.

Frequently Asked Questions About Creo

Can Creo open files from other CAD systems?

Yes, Creo Unite Technology opens native files from SolidWorks, CATIA, NX, and other major CAD platforms without conversion. The software also imports neutral formats like STEP, IGES, STL, and others. You can edit imported geometry using direct modeling tools and incorporate external designs into your assemblies while maintaining update links to source files.

Does Creo include simulation capabilities?

Creo includes Simulation Live for real-time structural, thermal, and modal analysis during design. Advanced simulation options provide detailed finite element analysis, computational fluid dynamics, and motion simulation. These tools work directly with your 3D models without requiring export to separate analysis software.

How does Creo handle late-stage design changes?

Creo's parametric foundation maintains relationships between features, so changes automatically propagate through dependent geometry. You can modify designs without rebuilding models from scratch. The direct modeling tools allow quick edits to imported components or legacy geometry where parametric structure isn't available, giving you flexibility to handle urgent modifications efficiently.

What file formats does Creo support?

Creo works with native files from SolidWorks (.sldprt, .sldasm), CATIA (.CATPart, .CATProduct), NX (.prt), and industry-standard formats including STEP, IGES, STL, JT, and others. The software maintains geometric accuracy and preserves metadata like material properties and manufacturing annotations during import and export operations.

Is Creo suitable for large assemblies?

Yes, Creo manages assemblies with tens of thousands of components efficiently. The software uses on-demand loading and lightweight representations to maintain performance while providing access to full geometry when needed. Large assembly tools help you navigate complex product structures, check interferences, and manage configurations across extensive designs.

Can Creo generate manufacturing documentation automatically?

Creo automatically generates 2D production drawings from 3D models, creating views, sections, dimensions, and annotations based on industry standards. When you update 3D geometry, drawings refresh automatically to reflect those changes. The software also produces bill of materials, assembly instructions, and other manufacturing documentation directly from your design data.