Purchase Comsol Multiphysics Software

January Sale!

Limited time: 5% discount on all products! Ends February 1.

Comsol Multiphysics

| Version | Price & Buy |

|---|---|

| 6.4 Build 293 x64 | |

| 5.6.0.401 x64 | |

| 4.4 Update 2 x32+x64 |

What Is COMSOL Multiphysics 6.3?

COMSOL Multiphysics 6.3 is an engineering simulation platform that solves problems involving multiple interacting physics phenomena within a single environment. When you design motors, optimize acoustic systems, or evaluate high-voltage equipment safety, real-world performance depends on electromagnetics, heat transfer, structural mechanics, and fluid flow working together—not in isolation. This version eliminates the need to manually couple separate software tools or write custom integration code.

Understanding Multiphysics in Engineering

Most engineering challenges involve simultaneous physical processes. A transformer generates electromagnetic fields while managing heat dissipation and mechanical stress from expansion. A microphone converts acoustic pressure into electrical signals while accounting for material properties and structural resonance. Version 6.3 handles these coupled phenomena automatically, letting you focus on design decisions rather than numerical methods.

One Platform for All Physics Domains

The software provides pre-configured interfaces for electromagnetics, acoustics, structural mechanics, fluid dynamics, heat transfer, and chemical reactions. You define geometry once and apply multiple physics modules without reformatting data or exporting between applications. Engineers at ABB used this approach to create digital twins of electromagnetic flowmeters, predicting field performance without physical prototypes.

How Does COMSOL 6.3 Reduce Your Design Timeline?

Version 6.3 introduces three acceleration technologies that compress simulation cycles from days to hours. GPU processing, automated geometry preparation, and AI-trained surrogate models each address different bottlenecks in the design process. These aren't incremental improvements—they fundamentally change how fast you can validate concepts and iterate designs.

25x Faster Acoustic Simulations with GPU Technology

New in COMSOL 6.3, GPU acceleration delivers up to 25x speedup for transient acoustics simulations and neural network training when using compatible Nvidia graphics cards. What previously required overnight compute clusters now runs during lunch breaks. L-Acoustics, a professional audio company, used similar acceleration to optimize bass reflex speakers for concert halls—running hundreds of design variations that would have been impractical with CPU-only processing.

Eliminate Hours of Manual Geometry Preparation

Industrial CAD models contain manufacturing details—fillets, chamfers, bolt holes—that complicate meshing without improving simulation accuracy. Version 6.3's automated tools identify and remove these features, repair surface defects, and optimize geometry for analysis. In best-case scenarios, preparation time drops from several hours to under ten minutes. One mechanical engineer reported solving a thermal-fluid problem with complex geometry "in one afternoon" instead of the week anticipated with manual mesh preparation.

Instant Results with AI-Trained Simulation Models

Once you've run parametric studies, COMSOL 6.3 trains neural networks that replicate simulation behavior at near-instant speed. These surrogate models enable real-time design exploration through standalone applications, letting non-technical team members evaluate configurations without running full physics calculations. Mahindra & Mahindra deployed this approach across manufacturing, design, and CAE teams to accelerate automotive component development.

What New Capabilities Does Version 6.3 Add?

This release introduces features not available in any previous COMSOL version. The Electric Discharge Module addresses safety-critical applications in power systems and electronics, while electromagnetic enhancements improve accuracy for motors, transformers, and MEMS devices. These aren't refinements of existing tools—they're entirely new simulation capabilities.

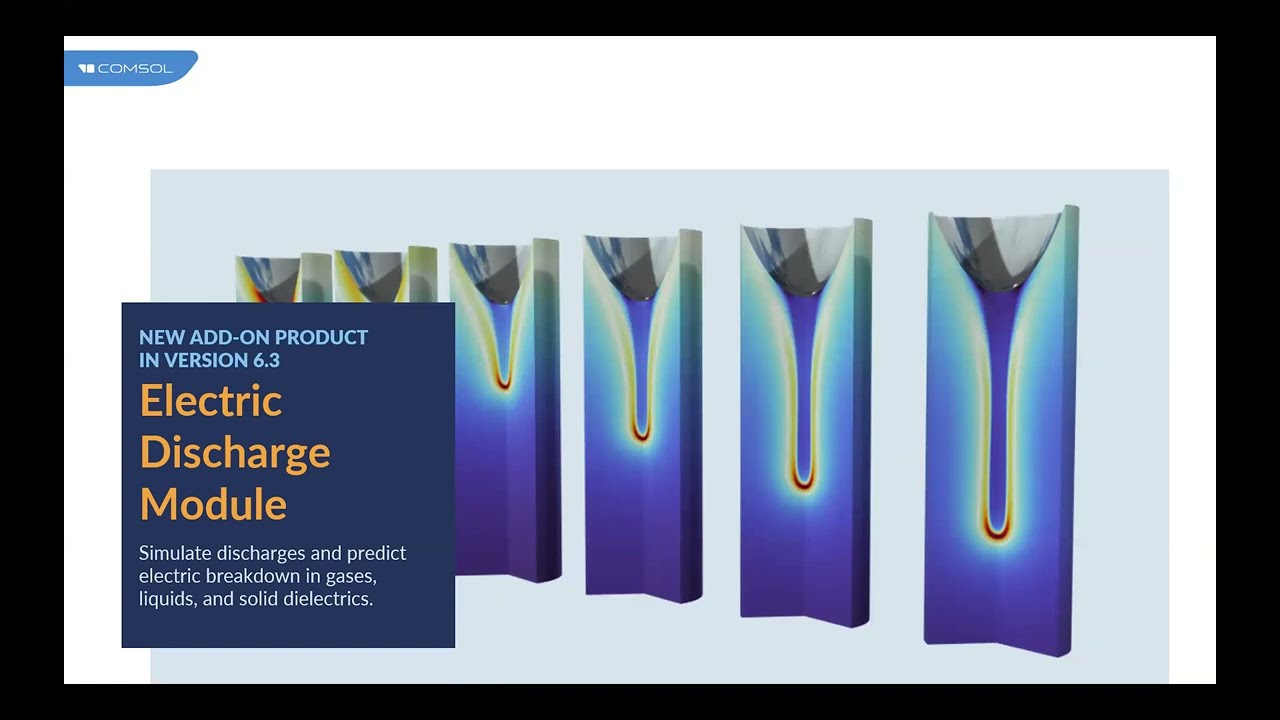

Electric Discharge Module: Simulate Complex Breakdown Phenomena

New in COMSOL 6.3, the Electric Discharge Module enables detailed simulation of electrical breakdown in gases, liquids, and solids. You can now evaluate static discharge risks in automotive electronics, model transformer oil breakdown under high voltage, or design circuit breakers that safely interrupt fault currents. The module handles the complicated multiphysics coupling—electromagnetics, fluid flow, plasma chemistry, and heat transfer—behind a streamlined interface. Engineers at Pinggao Group used COMSOL's multiphysics capabilities to design gas-insulated switchgear while significantly reducing development costs.

Improved Accuracy for Motors, Transformers, and MEMS Devices

COMSOL 6.3 introduces laminated iron core modeling that accounts for insulation layers between sheets in motors and transformers, capturing losses and magnetic behavior other tools approximate. Enhanced electrostatic force calculations for MEMS devices reduce numerical errors in pull-in voltage predictions. The new litz wire modeling feature simulates individual conductor strands in high-frequency applications, and DQ excitation support simplifies permanent magnet motor analysis.

| Version 6.3 Enhancement | Engineering Application | Business Impact |

|---|---|---|

| GPU Acceleration (25x speedup) | Transient acoustics, surrogate model training | Compress weeks of parametric studies into days |

| Electric Discharge Module | High-voltage equipment, static discharge protection | Prevent field failures through virtual safety testing |

| Automated Geometry Prep | Industrial CAD import for simulation | Reduce pre-processing from hours to minutes |

| Laminated Iron Modeling | Motor and transformer electromagnetic design | Improve efficiency predictions and reduce prototyping |

| Neural Network Surrogates | Real-time design apps for non-specialists | Democratize simulation across departments |

How Does COMSOL Integrate with Your CAD and Existing Tools?

Engineers rarely work in isolation. Your simulation results need to inform CAD models, inform colleagues who don't use simulation software, and fit within automated design workflows. COMSOL 6.3 provides API-level control and AI assistance to customize integration without hiring specialized programmers.

Customize Models On-the-Fly with Java API Environment

New in COMSOL 6.3, the interactive Java environment lets you modify models using the COMSOL API without leaving the interface. You can prototype parametric sweeps, automate post-processing, or build custom physics couplings through a Method Editor with syntax highlighting and code completion. This bridges the gap between graphical modeling and programmatic control—useful when you need batch processing across compute clusters or integration with external databases.

AI Chatbot Assistance for Model Development

Version 6.3 includes optional ChatGPT integration that provides context-aware coding help within the Java environment. When you're unsure of API syntax or troubleshooting a script, the chatbot suggests corrections and explains methods without requiring external documentation searches. This feature reduces the barrier to automation for engineers who don't write code daily.

Which Industries Benefit Most from COMSOL 6.3?

Multiphysics simulation applies across industries, but version 6.3's enhancements particularly benefit sectors dealing with acoustic optimization, electromagnetic safety, and high-voltage equipment design. Companies in automotive, power systems, and electronics manufacturing have already deployed these capabilities in production environments.

Automotive: Sound Design and Static Discharge Prevention

HARMAN International uses COMSOL's acoustics capabilities to design premium audio systems for luxury vehicles, optimizing speaker placement and cabin acoustics with the entire car geometry in mind. The new Electric Discharge Module addresses another automotive challenge: protecting sensitive electronics from static discharge during assembly and operation. Simulating discharge paths virtually is faster and more comprehensive than physical testing alone.

Power and Renewable Energy: Equipment Safety and Grid Optimization

ABB engineers use multiphysics simulation to design instrument transformers and sensors that withstand overvoltages in submersible underground vault applications. The Electric Discharge Module in version 6.3 extends this capability to circuit breaker design and transformer oil breakdown analysis. Polar Night Energy demonstrated another application by optimizing a 42-ton sand-based thermal storage system using heat transfer modeling, helping reduce nonrenewable fuel consumption in Finland's district heating networks.

Electronics Manufacturing: Reliability and MEMS Precision

MEMS devices require precise electrostatic force calculations to predict pull-in voltage and mechanical deflection. Version 6.3's enhanced algorithms reduce numerical errors that previously required experimental validation. The software's equation-based modeling lets engineers implement custom physics for novel device architectures. As one optical engineer noted, the ability to couple optical, mechanical, thermal, and electrical simulations in one environment eliminates weeks of manual integration work.

Key Applications Where COMSOL 6.3 Delivers Measurable Value

- Acoustic optimization for automotive cabins, HVAC systems, and professional audio equipment

- High-voltage equipment safety evaluation including circuit breakers and transformers

- Motor and generator electromagnetic design with laminated core accuracy

- Static discharge protection for electronics manufacturing and control panels

- MEMS device design with improved electrostatic force precision

- Thermal management for power electronics and battery systems

How to Get Started with COMSOL Multiphysics 6.3?

The software balances depth with accessibility. Pre-configured physics modules handle the mathematical complexity of coupled field equations, while the interface exposes parameters you actually control in physical systems. This design philosophy means you can run meaningful simulations shortly after installation rather than spending weeks in prerequisite courses.

Pre-Configured Physics for Immediate Use

The Electric Discharge Module exemplifies COMSOL's approach: complicated multiphysics coupling—Maxwell's equations, Navier-Stokes fluid flow, plasma chemistry reactions, and heat diffusion—comes pre-assembled. You specify electrode geometry, gas properties, and voltage conditions. The solver handles numerical stability and convergence automatically. Users consistently report that problems requiring custom equation systems in other software work "out of the box" in COMSOL.

Access Training Resources and Expert Support

The Application Gallery contains hundreds of validated models spanning industries and physics domains. You can download these as starting points, modifying geometry and parameters rather than building from scratch. Webinars, documentation, and professional services provide additional support. Customer reviews consistently mention "easily accessible support staff" who answer technical questions directly.

Frequently Asked Questions About COMSOL Multiphysics 6.3

Do I need special hardware for GPU acceleration?

GPU acceleration in COMSOL 6.3 requires a compatible Nvidia graphics card but remains optional. Simulations run on standard CPUs with multicore support. The GPU features benefit transient acoustics and neural network training specifically—other analyses use traditional CPU-based solvers. Most users evaluate GPU benefits after initial deployment rather than as a prerequisite.

What problems does the Electric Discharge Module solve?

The module simulates electrical breakdown in gases, liquids, and solids—phenomena critical for power equipment safety, static discharge prevention, and high-voltage insulation design. Applications include transformer oil breakdown testing, circuit breaker arc modeling, static discharge paths in electronics assembly, and plasma processing equipment design. This capability was unavailable in previous COMSOL versions.

Which CAD formats can COMSOL import?

COMSOL 6.3 imports industry-standard CAD formats including STEP, IGES, Parasolid, ACIS, and native formats from major CAD packages. The automated geometry preparation tools in version 6.3 handle industrial models that weren't originally created for simulation, removing manufacturing details and repairing surface defects that complicate meshing.

How do surrogate models benefit my team?

Neural network surrogates trained in version 6.3 replicate full physics simulations at near-instant speed. You can deploy these as standalone applications to colleagues who don't use simulation software, enabling real-time design exploration without requiring physics expertise. Automotive and manufacturing companies use this approach to democratize simulation insights across departments while protecting intellectual property in the underlying models.

What improvements does version 6.3 offer compared to 6.2?

Version 6.3 introduces the Electric Discharge Module (entirely new capability), GPU acceleration for acoustics and surrogate training (up to 25x speedup), automated geometry preparation tools, interactive Java environment with chatbot assistance, laminated iron modeling for motors and transformers, and enhanced MEMS electrostatic force calculations. These represent new features rather than incremental improvements to existing tools.