Buy Ansys Fluent Software

November 2025 Sale!

Limited time: 5% discount on all products! Ends December 1.

Ansys Fluent

| Version | Price & Buy |

|---|---|

| 6.3 32bit+64bit |

What Is Ansys Fluent 6.3 and What Problems Does It Solve?

Fluent 6.3 addresses the core challenge engineering teams face: balancing simulation accuracy with project deadlines. Traditional CFD workflows consume excessive time in mesh generation and solver convergence, often requiring multiple attempts before achieving reliable results. This version targets these bottlenecks with automated meshing technology and improved solver algorithms that deliver faster turnaround without compromising precision.

The software tackles three specific pain points that delay projects. Manual mesh creation for complex geometries can take days of engineering time, while convergence failures waste computational resources and require troubleshooting. Limited physics capabilities often force teams to use workarounds or export data to external tools for specialized analyses like emissions compliance.

Core Capabilities That Save Time

- Pressure-based coupled solver introduced in version 6.3 delivers faster solution times and improved convergence characteristics across diverse simulation types

- Polyhedral mesh generation creates meshes automatically with 5 to 7 times fewer cells than equivalent tetrahedral meshes while maintaining accuracy

- Dynamic mesh workflows now apply to steady-state series, eliminating repetitive setup for rotating equipment like impellers in mixing tanks

- File operations receive substantial speed improvements with optimized case and data read/write times reducing project overhead

Industries and Applications

Chemical process engineers use Fluent 6.3 for reactor design simulations with specialized slow chemistry and micromixing models. Environmental engineering teams leverage the comprehensive SOx and NOx emissions modeling for combustion systems and regulatory compliance analysis. Equipment manufacturers simulate mixing tanks, impellers, and rotating machinery with streamlined dynamic mesh capabilities that reduce pre-processing workload.

How Does Fluent 6.3 Reduce Simulation Time?

Version 6.3 introduces polyhedral meshing technology that fundamentally changes pre-processing efficiency. Where a tetrahedral mesh might require 500,000 cells to capture geometry details, a polyhedral mesh achieves equivalent accuracy with 70,000 to 100,000 cells. Fewer cells mean shorter solve times, reduced memory consumption, and the ability to run larger problems on existing hardware.

The pressure-based coupled solver pairs velocity and pressure equations, solving them simultaneously rather than sequentially. This approach accelerates convergence for many flow types, particularly compressible flows and cases where traditional segregated solvers struggle. Projects that previously required overnight runs can often complete in hours, directly impacting how many design iterations teams can evaluate per day.

| Mesh Type | Cell Count for Typical Geometry | Pre-Processing Time | Convergence Speed |

|---|---|---|---|

| Tetrahedral Mesh (Traditional) | 400,000 - 600,000 cells | Manual refinement required | Baseline reference |

| Polyhedral Mesh (Fluent 6.3) | 60,000 - 100,000 cells | Automated generation | Faster convergence with fewer cells |

Automated Polyhedral Meshing Advantages

Polyhedral meshes adapt to complex geometries with the flexibility of unstructured grids but without the computational penalty. The automatic generation process removes manual refinement loops where engineers traditionally adjust parameters, regenerate meshes, and check quality metrics repeatedly. User reports confirm achieving identical accuracy with dramatically reduced cell counts, translating to proportional savings in solution time.

Coupled Solver Speed Benefits

The coupled solver improves robustness for challenging simulations that fail to converge with standard methods. Rather than debugging solver settings and restarting runs, teams achieve successful solutions on the first attempt more consistently. Memory optimization in version 6.3 further enhances performance, particularly for the density-based solver used in high-speed flow applications.

What Are the Key Improvements in Fluent 6.3?

Enhanced Dynamic Mesh Functionality

New in version 6.3, dynamic mesh capabilities extend to steady-state simulation series. Engineers modeling rotating equipment previously configured dynamic meshes for each impeller position or operational state separately. The enhanced workflow reuses mesh motion definitions across multiple steady-state cases, eliminating redundant setup work. Mixing tank simulations with baffles and impellers particularly benefit from this streamlined approach.

- Steady-state series support for moving objects reduces pre-processing time for parametric studies

- Complex object motion receives additional flexibility for industrial equipment with multiple moving components

- Reusable motion definitions simplify iterative design processes for rotating machinery

Expanded Physics Modeling

Fluent 6.3 adds comprehensive SOx and NOx emissions prediction, addressing regulatory compliance requirements within the core CFD platform. Chemical process applications gain specialized reacting flow models including slow chemistry formulations for detailed kinetic mechanisms and micromixing models for reactor design. Multiphase modeling improvements enhance transient solution accuracy and extend the operating regimes where these models produce reliable results.

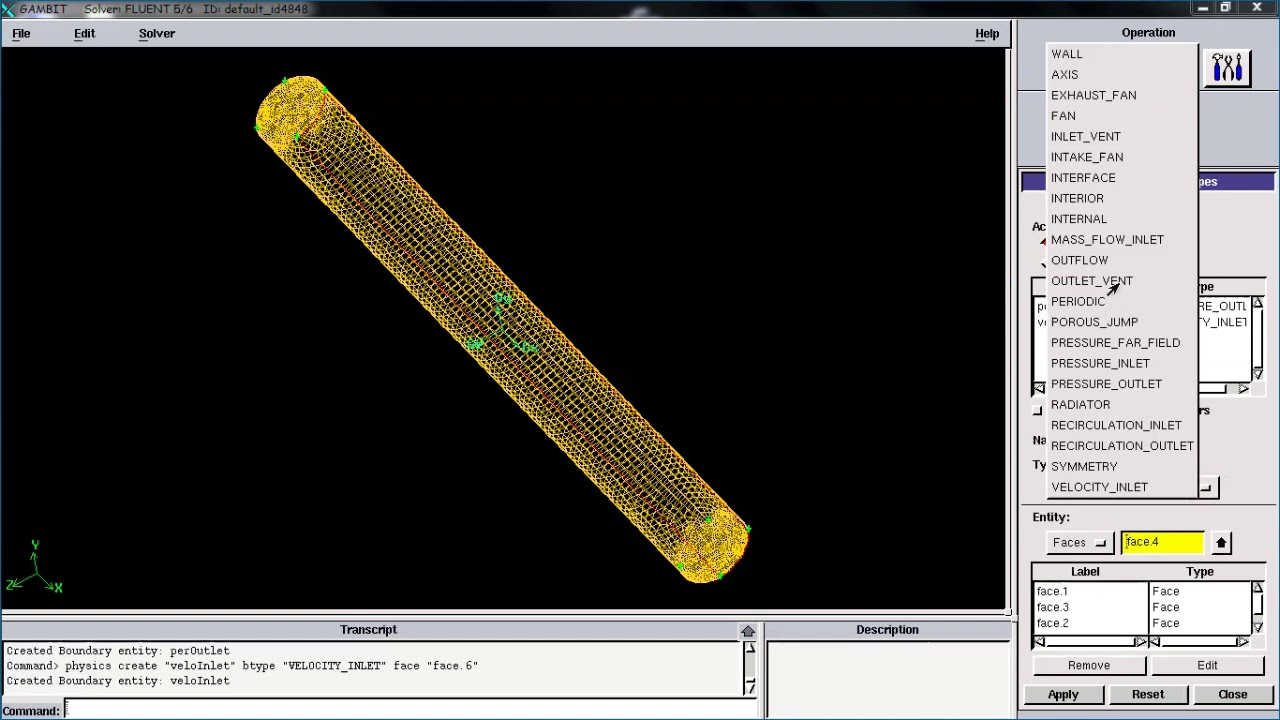

How Does Fluent 6.3 Handle Complex Geometries?

Polyhedral cells naturally accommodate irregular shapes and intricate flow passages without the geometric constraints of structured hexahedral meshes. Each polyhedral cell connects to numerous neighbors, capturing flow directionality more effectively than tetrahedral cells that require many more elements to achieve similar resolution. This geometry flexibility proves valuable for aerospace components with complex internal passages, industrial equipment with non-uniform flow domains, and process equipment with irregular vessel shapes.

| Application Type | Geometry Challenge | Polyhedral Mesh Benefit |

|---|---|---|

| Aerospace Components | Intricate internal cooling passages | Unstructured flexibility without cell count penalty |

| Industrial Equipment | Complex flow paths and irregular domains | Automatic generation for difficult geometries |

| Process Equipment | Vessel internals with baffles and impellers | Efficient mesh for rotating equipment simulations |

Polyhedral Mesh Technology

The automatic nature of polyhedral mesh generation removes the trial-and-error refinement process. Engineers receive usable meshes without manual cell zone manipulation, boundary layer adjustment, or quality improvement iterations that consume project time. Version 6.3 generates these meshes with substantially fewer cells than tetrahedral alternatives—users report reductions of 80-85% while preserving solution accuracy.

Practical Geometry Applications

Real-world CFD projects involve geometries imported from CAD systems that rarely consist of simple shapes. Polyhedral meshing handles these practical challenges: components with thin walls adjacent to large volumes, equipment with complex internal features, and assemblies where clearances and gaps require mesh resolution. The technology adapts to these variations automatically rather than demanding geometry simplification that might compromise simulation fidelity.

What Multiphase and Reacting Flow Capabilities Does Fluent 6.3 Offer?

Multiphase flow modeling receives accuracy improvements in version 6.3, particularly for transient simulations tracking multiple phases over time. The enhancements extend the operational regimes where these models produce trustworthy results, allowing engineers to simulate conditions previously outside reliable prediction ranges. Oil and gas applications, chemical processing with liquid-vapor systems, and fluid handling equipment with phase interactions all benefit from these refinements.

Enhanced Multiphase Modeling

- Transient multiphase solutions achieve improved accuracy for time-dependent phase interactions

- Extended operating regime coverage allows simulation of broader process conditions

- Phase interaction handling receives algorithmic improvements for complex flow scenarios

Reacting Flow and Emissions Modeling

The slow chemistry model in Fluent 6.3 enables detailed kinetic mechanism implementation for chemical processes where reaction rates significantly influence flow behavior. Micromixing capabilities support reactor design by capturing the interaction between turbulent mixing and chemical reactions at scales smaller than computational cells. SOx and NOx emissions prediction provides comprehensive environmental assessment directly within simulation workflows, eliminating data export to external post-processing tools.

Combustion systems, industrial furnaces, and process heaters use the emissions modeling for regulatory compliance analysis. The integrated approach means concentration predictions accompany flow field and temperature distributions in a single simulation, providing complete environmental performance insight.

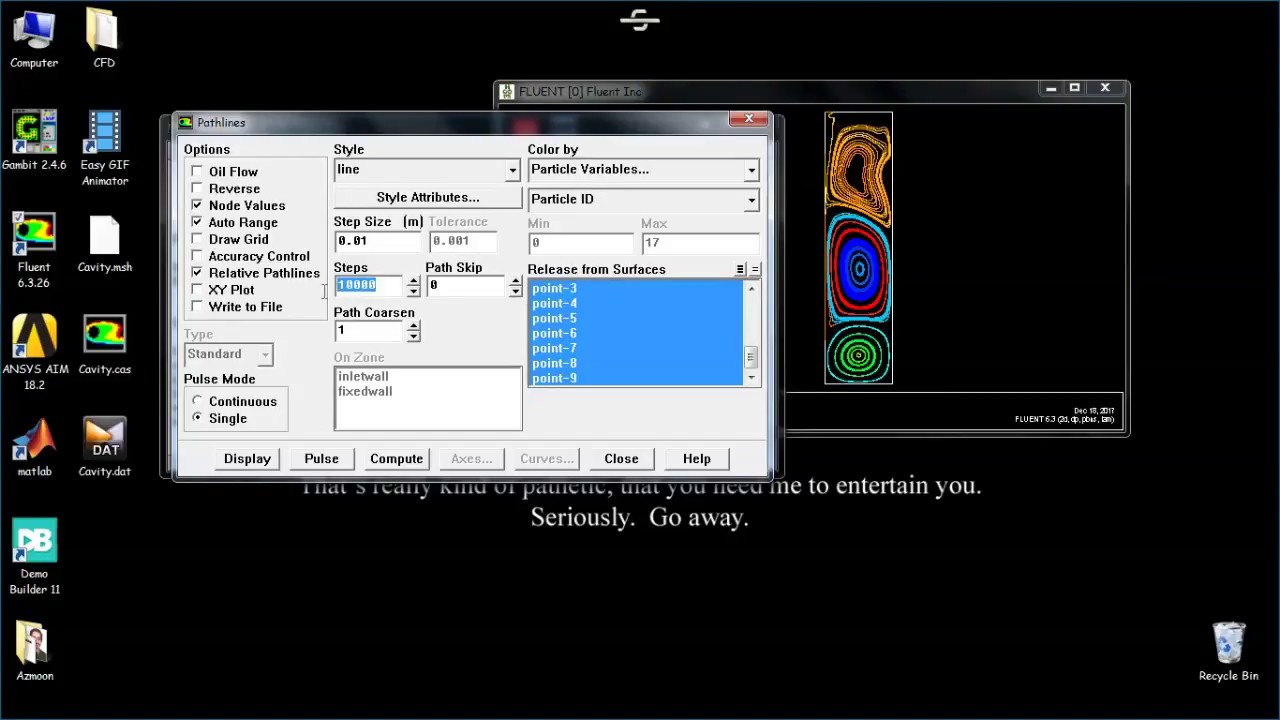

How to Get Started with Ansys Fluent 6.3

Fluent 6.3 maintains interface familiarity for users of previous versions while introducing workflow enhancements that integrate seamlessly. Existing simulation projects migrate forward without requiring extensive setup recreation. The polyhedral meshing and coupled solver options appear as additional capabilities within established menus and procedures.

Workflow Integration Benefits

Teams already using Fluent will recognize the core interface and workflow structure. New meshing options and solver algorithms supplement existing capabilities rather than replacing them, allowing gradual adoption based on project requirements. File format compatibility ensures smooth project continuity, with improved read and write performance reducing the time spent on file operations.

Frequently Asked Questions About Fluent 6.3

Technical Questions

Q: What makes the coupled solver faster?

The pressure-based coupled solver in Fluent 6.3 solves velocity and pressure equations simultaneously rather than sequentially, improving convergence speed and robustness for many flow types including compressible flows.

Q: How much time does polyhedral meshing save?

Polyhedral meshes automatically generate with 5 to 7 times fewer cells than tetrahedral meshes for equivalent accuracy, directly reducing both mesh creation time and solution time proportionally.

Q: Can I use dynamic meshes for steady-state problems?

Yes, version 6.3 introduces dynamic mesh capabilities for steady-state simulation series, allowing reusable motion definitions for rotating equipment like impellers across multiple operational cases.

Q: What emissions modeling does Fluent 6.3 include?

Fluent 6.3 adds comprehensive SOx and NOx modeling capabilities for combustion and industrial process simulations, enabling regulatory compliance analysis within the CFD workflow.

Application Questions

Q: What industries benefit most from Fluent 6.3?

Chemical processing for reactor design, environmental engineering for emissions compliance, and equipment manufacturing for mixing and rotating machinery applications gain the most from version 6.3 enhancements.

Q: Does Fluent 6.3 work with complex geometries?

Polyhedral meshing handles intricate geometries with unstructured mesh flexibility but without the computational overhead of large tetrahedral meshes, making complex industrial geometries more practical to simulate.

Q: What's different about multiphase modeling in this version?

Version 6.3 improves transient multiphase solution accuracy and extends the operating regimes where multiphase models produce reliable results for liquid-vapor and multi-component flow systems.

Q: How does version 6.3 improve workflow efficiency?

Automatic polyhedral mesh generation, faster convergence with the coupled solver, and reusable dynamic mesh setups reduce the time engineers spend on pre-processing and troubleshooting convergence issues.