Purchase Altair Inspire Software

January Sale!

Limited time: 5% discount on all products! Ends February 1.

Altair Inspire

| Version | Price & Buy |

|---|---|

| 2026.0 | |

| 2025.0 | |

| 2024.1.1 | |

| 2023.0 | |

| 2022.3.1 | |

| 2021.2.3 |

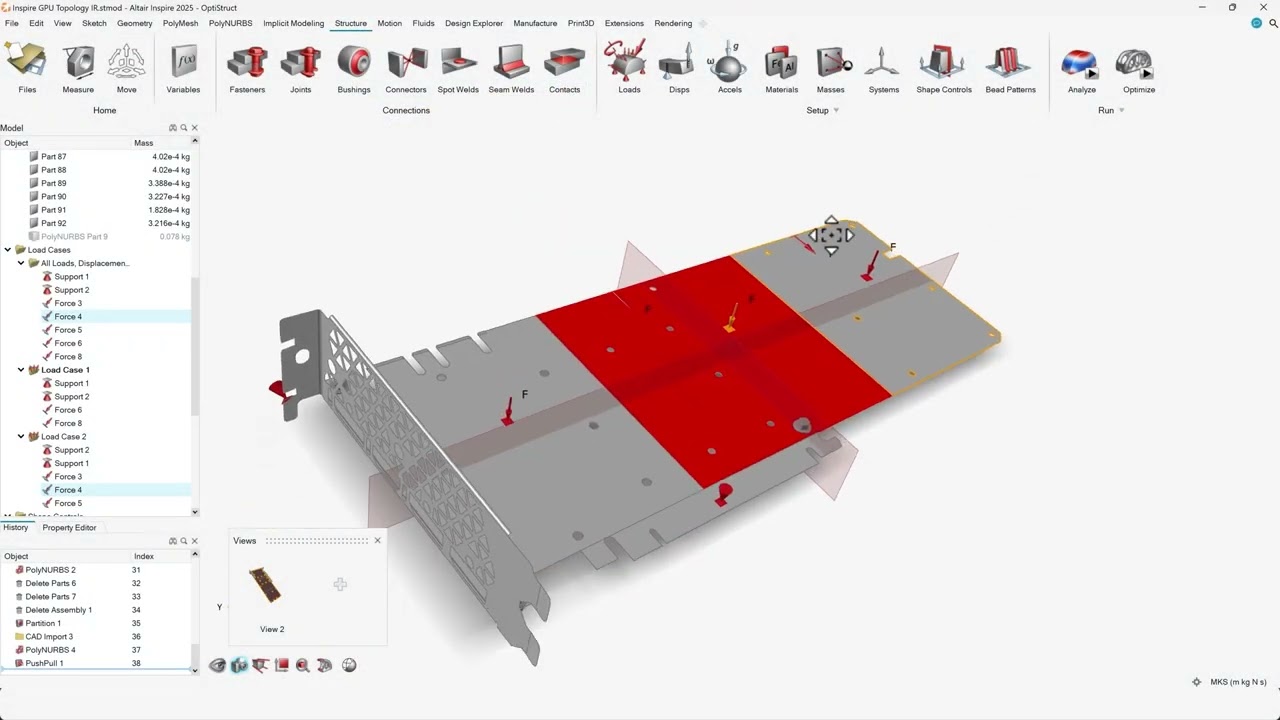

How Does Inspire 2025 Transform Your Design Workflow?

Inspire 2025 changes how engineers approach design validation by embedding real-time artificial intelligence directly into the modeling environment. Rather than consulting separate help systems or external specialists, you receive contextual guidance as you work, making complex simulations feel intuitive even for first-time users.

The platform eliminates fragmented workflows where you'd move between CAD tools, simulation software, and manufacturing prep applications. Your design, analysis, iteration, and production planning happen in one unified environment. This single-platform approach means your thermal analysis geometries, structural models, and 3D print files stay synchronized without manual translation or format conversion headaches.

Key Workflow Improvements with Inspire 2025

- Real-time AI Copilot provides task-specific guidance without leaving the design interface

- Parametric design variables update instantly across all connected analyses and geometry models

- PhysicsAI generates outcome predictions before you run full simulations, validating design direction in seconds

- Manufacturing preparation modules automatically generate print parameters or machining paths from validated designs

What Problems Does Inspire 2025 Solve for Engineers?

Complex geometries previously required either workarounds or external specialist consultation. Inspire 2025's implicit modeling handles lattice structures, porous media filters, and intricate cooling passages with native support. You're not translating compromised CAD approximations—the software understands your actual geometry intent.

Simulation expertise becomes less of a barrier. PhysicsAI learns from your historical projects to predict physics behavior, removing the setup complexity that typically slows validation cycles. New team members ramp up faster because the Copilot assistant guides them through analysis setup, reducing knowledge transfer burden.

Design confidence increases when PhysicsAI predictions align with traditional simulations. You validate concepts with predictions before running computationally expensive full analyses, eliminating uncertainty during critical early-stage decisions. This particularly matters when you need stakeholder buy-in on design direction—data-backed predictions carry more weight than intuition alone.

Problems Inspire 2025 Addresses

- Geometry complexity in aerospace cooling ducts and filter components

- Long setup time for thermal and CFD analyses reducing iteration speed

- Expertise gap when simulation specialists aren't available

- Uncertainty during design concept evaluation phase

- Tool fragmentation creating file compatibility issues

Why Choose Simulation-Driven Design Over Traditional Methods?

Physical prototyping validates products but introduces cost and delay. A single prototype iteration might require weeks of fabrication and testing, consuming budget before you've validated core assumptions. Simulation-driven design compresses this timeline—you explore multiple geometric variations virtually before committing to physical validation.

The financial impact extends beyond time savings. Early-stage validation catches design flaws when changes cost minimal effort. Detecting a cooling duct geometry issue during Inspire simulation requires geometry adjustment in minutes. Finding the same issue after prototype fabrication and thermal testing costs thousands in material, labor, and schedule delay.

Inspire 2025 makes this validation accessible across your organization. Mechanical engineers validate structural adequacy. Thermal specialists simulate heat transfer. Manufacturing engineers confirm producibility—all on the same model, all seeing real-time updates. This cross-functional visibility prevents costly surprises during handoff phases.

Simulation-Driven Validation vs. Traditional Prototyping

| Aspect | Simulation-Driven | Traditional Prototyping |

|---|---|---|

| Iteration Speed | Hours for geometry changes | Weeks for fabrication |

| Cost per Iteration | Minimal (CAD adjustments) | Substantial (materials, labor) |

| Design Variations | Dozens explored quickly | Few concepts validated |

| Early Issue Detection | Concept phase | Post-prototype testing |

| Cross-Team Visibility | Real-time model access | Design-phase handoffs |

| Documentation | Complete digital record | Physical prototype remains |

How to Design Complex Geometries Inspire Cannot Handle Before?

New in Inspire 2025, implicit modeling removes traditional CAD surface limitations. Lattice structures for aerospace components now export with full topology preserved rather than simplified approximations. You design the actual structure needed for performance, not a printable workaround.

Porous media simulation enables filter and separator designers to test complex internal geometry behavior. Rather than assuming pressure drop or assuming flow distribution, you model actual pore geometry and simulate fluid behavior through the media. CFD analysis includes natural convection boundary conditions, so thermal engineers validate cooling effectiveness without external post-processing.

The practical impact appears in additive manufacturing workflows. Complex internal cooling passages for molds or engines can now be validated for both structural integrity and thermal performance before printing. You confirm the lattice geometry handles loads while efficiently transferring heat—all in Inspire before production commitment.

Applications Enabled by Implicit Modeling

- Aerospace cooling ducts with complex internal geometry and natural convection

- Lattice structures for weight optimization in aerospace and automotive

- Filter and separator element design with porous media simulation

- Additive manufacturing internal features (conformal cooling, lightweight structures)

- Thermal management for electronics with complex internal passages

Which Industries and Applications Benefit Most From Inspire 2025?

Aerospace and Thermal Engineering

Cooling system designers validate heat transfer through complex geometries before manufacturing. Wing components optimize weight while maintaining structural margins. Landing gear assemblies confirm thermal stability during high-energy braking events.

Additive Manufacturing

3D printing facilities use Inspire to validate conformal cooling passages in injection molds, reducing print-to-use cycle time. Product designers confirm lattice geometry provides required strength while achieving weight targets. The Print3D module automatically generates slicing parameters, streamlining design-to-production handoff.

Product Design and Structural Validation

Consumer products undergo fast concept-to-validation cycles. Thermal management for portable electronics gets validated before prototyping. Structural integrity of lightweight designs confirms safety before manufacturing scale-up. Multi-body systems validate motion and load transfer before assembly.

Filter and Component Specialization

Companies designing air filters, liquid separators, or flow control devices model actual porous geometry behavior. Pressure drop and flow distribution get validated numerically rather than through physical testing. Complex shaped filters optimize surface area while maintaining structural integrity.

How to Integrate Inspire 2025 Into Your Design Process?

Start with parametric design foundation. Rather than static CAD geometry, establish key dimensional variables—wall thickness, channel diameter, lattice density, cooling passage pitch. These parameters drive your simulation analyses. When design direction changes, you update variables and regenerate analyses rather than rebuilding from scratch.

PhysicsAI integration happens next. As your team completes simulations, PhysicsAI learns patterns from your historical projects. On new designs with similar characteristics, PhysicsAI provides outcome predictions before full simulation. Validation cycles accelerate because you confirm physics direction with seconds-fast predictions before investing computational time in detailed analysis.

Manufacturing handoff streamlines when you're already in Inspire. Structural validation confirms the geometry meets performance requirements. The Print3D or manufacturing module automatically generates production parameters from the validated design. Design files transfer directly to production without conversion, eliminating format compatibility concerns.

Integration Workflow

- Establish parametric design variables for key geometry dimensions

- Run initial Inspire simulations to establish baseline performance

- Enable PhysicsAI learning from completed analyses

- Iterate geometry using parameter updates and PhysicsAI predictions

- Leverage Print3D or manufacturing modules for production prep

- Transfer validated designs directly to manufacturing systems

Common Questions About Inspire 2025 Simulation Capabilities

Can Inspire handle my complex aerospace cooling system?

Inspire 2025 natively supports the complexity aerospace engineers encounter. Implicit modeling preserves intricate passage geometry. CFD includes natural convection boundary conditions relevant to aerospace thermal management. PhysicsAI predictions work with aerospace-specific geometry patterns your team has modeled previously. Most aerospace cooling designs validate effectively in Inspire without geometric compromises.

How accurate is PhysicsAI for my specific application?

PhysicsAI accuracy improves as your project history accumulates. Initial predictions establish baseline accuracy by comparing against your completed simulations. As you model more projects with similar characteristics, PhysicsAI learns application-specific patterns and prediction precision increases. The system learns your modeling approach and typical parameter ranges, making predictions increasingly tailored to your design methodology.

What's the learning curve for new simulation users?

The Copilot assistant guides setup for first-time simulations. Rather than consulting manuals, you receive contextual prompts explaining each step. Experienced simulation engineers complete basic CFD or structural analysis setups in Inspire without training. New engineers typically need introduction to your simulation workflow and standards, but Inspire's interface reduces software-specific learning barriers compared to traditional simulation platforms.

Does Inspire 2025 integrate with my existing CAD files?

Import processes handle standard CAD formats from major platforms. Parametric relationships sometimes require rebuilding in Inspire to capture design variables, but geometry transfer is straightforward. Many teams maintain CAD in their original tool for design documentation while using Inspire for validation and manufacturing prep. Files stay coordinated through established naming conventions and project structure.

Can I use Inspire 2025 for motion analysis and multi-body systems?

Inspire 2025 includes motion analysis capabilities for multi-body systems. Mechanical assemblies with moving components, joints, and constraints can be modeled and analyzed. Load and stress results transfer between motion analysis and structural analysis, so you validate that moving components handle computed loads safely. This particularly benefits mechanism design, robotics, and motion-dependent validation.

Why Inspire 2025 Represents the Future of Design Engineering

Design software is moving toward integrated prediction and validation environments. Inspire 2025 demonstrates this direction with AI assistance that feels natural rather than bolted-on. When PhysicsAI predictions validate your design direction in seconds, traditional separate-tool workflows feel slower by comparison.

The implicit modeling capability addresses a real limitation of traditional CAD. Complex geometries no longer require engineer workarounds. Designers specify actual geometry needed for performance, not compromised approximations CAD happens to support. As manufacturing increasingly enables complex geometries through additive processes, design tools must evolve to handle this complexity natively.

Cross-functional teams see immediate communication improvements when everyone works from the same validated digital model. Design iterations don't require file conversions or manual synchronization. This unified environment reduces handoff delays and catches conflicts before they reach manufacturing. The financial and schedule benefits compound as projects move through development cycles.

Inspire 2025 proves that engineering software can be both powerful and accessible. New users don't need weeks of training to run meaningful simulations. Experienced engineers gain efficiency through PhysicsAI predictions and parametric iteration speed. The platform accommodates expertise progression—beginning users access guided workflows while experienced specialists leverage advanced capabilities directly.